Next Generation Medical Infusion Pump

This case study summarizes the systems engineering aspects of the next-generation SymbiqTM IV (intravenous) medical pump development, developed by the Abbott Laboratories spinoff company Hospira, Inc., and documented in detail in Chapter 5 of the National Research Council book, “Human-System Integration in the System Development Process” [Pew-Mavor 2007]. As described in [Pew-Mavor 2007], its purpose is “to deliver liquid medications, nutrients, blood and other solutions at a programmed flow rates, volumes and time intervals via intravenous and other routes to a patient, primarily for hospital use with secondary limited feature use by patients at home.”

Domain Background

This case study provides insight into the use of systems engineering practices in a medical application.

Analysis of Case Study

The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine. The study was supported by Award Number W911NF-05-0150 and FA5650-06-1-6610 between the National Academy of Sciences, the U.S. Department of the Army, and the U.S. Department of the Air Force.

Case Study Description

In creating a next-generation product, Hospira proposed to introduce new IV pump features: multi-channel vs. single-channel liquid delivery; ability to gang multichannel devices together; associated user-programming capabilities and programmable drug libraries for specifying parallel delivery of liquids; use of color touchscreen devices; integration with numerous types of hospital information systems; ease of use for both medical personnel and patients at home; handling of potential hardware, software, and human-user faults; compliance with U.S. and international safety standards; use of alternating-current or battery power; and the ability to be cost-competitive and attractive to traditional medical and hospital administration personnel. Many of these desiderata are highly coupled, such as multichannel hardware controls, concurrent software synchronization, distinctive displays and alarms for multichannel devices, and rigorous medical safety standards.

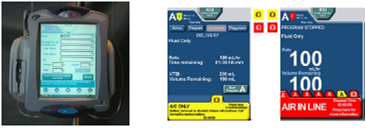

Views of the resulting SymbiqTM pump are shown in Figures 1-1 and 1-2. Its systems engineering involved a great deal of concurrent analysis and engineering of its hardware, software, human factors, operational, business, and safety aspects. It has been a commercial success, and won the 2006 Human Factors and Ergonomics Society’s User-Centered Product Design Award and the 2007 Medical Design Excellence Award.

Figure 1-1 Symbiq™ Pump Industrial Design

Figure 1-2 Two Channel IV Pumps with Left Channel Illuminated

Not only were there numerous technical challenges, but also there were challenges in systems engineering of a product and a life-cycle operational concept that would produce satisfactory outcomes for a wide variety of product and operational stakeholders, whose value propositions were often in some conflict. Some customers wanted numerous features that would require a complex user interface, while others wanted a simple, easy-to-learn and use interface. Some users wanted the most advanced color-touchscreen displays available, while others wanted a simpler, cheaper product that was harder to misuse via inadvertent screen touches. Some organizations felt that a minimal interpretation of the required safety features would be acceptable, while others advocated ultrahigh assurance levels. Some marketing personnel wanted a quick development and fielding of the basic product to capture market share, while maintainers wanted initial built-in life cycle support, maintenance, and diagnostic capabilities.

In such situations, many organizations focus on making quick requirements decisions and rapidly proceeding into development. However, Hospira’s understanding of the uncertainties and risks caused them to pursue a risk-driven, incremental-commitment course of buying information to reduce risk, as emphasized in the SEBoK Part 3 Knowledge Area on Risk Management. As described in [Pew-Mavor 2007], they used a version of the Incremental Commitment Spiral Model (ICSM) summarized in the SEBoK Part 3 Knowledge Area on representative systems engineering process models. The following sections describe the project’s incremental system definition progress through the ICSM Exploration, Valuation, Foundations, and Development phases. Some evolution of terminology has occurred: the [Pew-Mavor 2007] version uses ICM instead of ICSM, and Architecting phase instead of Foundations phase.

SymbiqTM Exploration Phase Summary

In the Exploration phase, the project carried out numerous stakeholder needs, technical opportunities, and business competition analyses, and determined ranges of preferred options. Stakeholder needs analyses included contextual inquiry via shadowing of nurses using IV pumps and followup interviews; and creating task flow diagrams, use environment analyses, and user profiles analyses. Technical opportunity analyses included initial conceptual designs of multichannel pump configurations, evaluation of commercially available single-color and multicolor display devices and touchscreen capabilities, and software approaches for specifying multichannel delivery options and synchronizing concurrent processes.

Business competition analyses included hiring a management and marketing planning firm to perform next-generation pump major competitor strengths and weaknesses analyses with respect to such capabilities as number of pump channels, therapies, programming options, air-in-line management, battery and alternating current capabilities, biomedical domain expertise, and alarms. Several key competitive advantages of a next-generation pump were identified, such as bar-code reading capability, small size and light weight, stand-alone functional channels, and extensive drug library, a high level of reliability, and clear mapping of screen displays and pumping channels.

Market research also identified market windows, market segment analyses, pricing alternatives, hospital purchasing decision analyses, and safety aspects. These were iterated with respect to focus groups of key thought leaders in critical care. The results were factored into a product concept plan, cost analysis, and business case analysis. These were independently reviewed by experts as part of the ICSM Valuation Phase Commitment Review process, which resulted in a go-ahead decision with an identification of several risks to be managed.

SymbiqTM Valuation Phase Summary

The Valuation phase focused on the major risks highlighted in the Valuation Commitment Review. These included the multi-channel pump options, the types of programmable therapies, the need for tailorable medication libraries, the display screen and user interface options, and the safety considerations. The Valuation phase also elaborated the product concept plan for the most attractive general set of options, including a development plan and operations plan, along with an associated cost analysis, risk analysis, and business case for review at the Foundations Commitment Review. The multi-channel pump options were explored via several hardware industrial design mockups and early usability test of the mockups. These included evaluation of such desired capabilities as semi-automatic cassette loading, special pole-mounting hardware, stacking of channels and total number of channels, and tubing management features. The evaluations led to overall choices of a semi-automatic cassette loading capability with a red-yellow-green LED display to indicate concerns with the loading mechanism and with the pump in general (Figure 1-2 shows the resulting capability on a two-channel pump with the left channel illuminated above the cassette loader).

Field exercises with prototypes of the pole mountings indicated the need for quick release/activation mechanisms, which were subsequently implemented. Risk analyses of alternative stacking mechanisms and total number of channels established a preference for side-by-side stacking, a decision to develop 1-channel and 2-channel units, and to support a maximum of 4 channels in a stacked configuration.

The types of programmable therapies considered included continuous delivery for a specified time period; patient weight-based dosing; piggyback or alternating delivery between the two channels; tapered or ramped-rate delivery, intermittent-interval delivery, variable-time delivery, and multistep delivery. These were evaluated via prototyping of the software on a simulated version of the pump complexes, and iterated until satisfactory versions were found.

Evaluation of the tailorable medication libraries addressed the issue that different hard and soft safety limits were needed for dosages in different parts of a hospital (emergency room, intensive care, oncology, pediatric care, etc.), and thus that a need for hospitals to be able to program their own soft limits (overridable by nurses with permission codes) and hard limits (no overrides permitted). Stakeholder satisfaction with the tailoring features was achieved via prototype exercises and iteration with representative hospital personnel.

A literature review was conducted to determine the relative advantages and disadvantages of leading input and display technologies, including cost and reliability data. After downselecting to three leading vendors of touch screen color LCD displays and further investigation of their costs and capabilities, a business risk analysis focused on the tradeoff between larger displays and customer interest in small-footprint IV pumps. The larger display was selected, based on better readability features and the reduced risk of wrong user entries with larger screen buttons. As shown in Figure 1-3, extensive usability prototyping was done with hardware mockups and embedded software that delivered simulated animated graphic user interface (GUI) displays to a touchscreen interface that was integrated into the hardware case. For grayscale versions of the three displays, the left one is single-color, the middle one is yellow at the bottom, and the right one is red at the bottom.

Figure 1-3 Sample Simulated GUI Screens

The safety risk analysis in the Valuation phase followed ISO 14971:2000 standards for medical device design, focusing on Failure Modes and Effects Analyses (FMEAs) based on the early high-level design, such as entry of excessive drug doses or misuse of soft safety limit overrides. Subsequent-phase FMEAs would elaborate these analyses, based on the more detailed designs and implementations.

As in the Exploration phase, the results of the Validation phase analyses, plans and budgets for the succeeding phases, the resulting revised business case, evidence of solution feasibility, and remaining risks with their risk management plans were reviewed by independent experts, and the ICSM Foundations Commitment Review was passed subject to a few risk level and risk management adjustments.

SymbiqTM Foundations Phase Summary

During the Foundations phase, considerable effort was focused on addressing the identified risks, such as the need for prototyping of the full range of GUI usage by the full range of targeted users, such as doctors and home patients, for interoperability of the Symbiq software with the wide variety of available hospital information systems, and for fully detailed FMEAs and other safety analyses. Comparable added effort went into detailed planning for development, production, operations, and support, providing more accurate inputs for business case analyses. GUI prototyping was done to a set of usability objectives, such as:

• 90 percent of experienced nurses will be able to insert the cassette the first time while receiving minimal training. 99 percent will be able to correct any insertion errors. • 90 percent of first time users with no training would be able to power the pump off when directed. • 80 percent of patient users would rate the overall ease of use of the IV pump 3 or higher on a 5-point scale of satisfaction with 5 being the highest value.

Similar extensive evaluations were done on the efficacy and acceptability of the audio alarms, including use of a patient and intensive care unit simulator that included other medical devices that produced noises and other distractions such as ringing telephones. This helped to adjust the alarms and the understandability of the visual displays.

Software interoperability risk management involved extensive testing of representative interaction scenarios between the SymbiqTM software and a representative set of hospital information systems. These resulted in several adjustments to the software interoperability architecture. Also, as the product was being developed as a platform for the next generation of infusion pump products, the software design was analyzed for overspecialization to the initial product, resulting in several revisions. Similar analyses and revisions were performed for the hardware design.

As the design was refined into complete build-to specifications for the hardware and the operational software, the safety analyses were elaborated into complete Failure Modes and Effects Analyses of the detailed designs. These picked up several potential safety issues, particularly involving the off-nominal usage scenarios, but overall confirmed a high assurance level for the safety of the product design. However, the safety risk assessment recommended a risk management plan for the Development phase to include continued FMEAs, thorough off-nominal testing of the developing product’s hardware and software, and extensive beta-testing of the product at representative hospitals prior to full release.

This plan and the other Development and Operations phase plans, product feasibility evidence, and business case analysis updates were reviewed at a Development Commitment Review, which resulted in a commitment to proceed into the Development phase.

SymbiqTM Development Phase Systems Engineering Summary

The Development phase was primarily concerned with developing and testing the hardware and software to the build-to specifications, but continued to have an active systems engineering function to support change management, operations, production, and support planning and preparation, and further safety assurance activities as recommended in the risk management plan for the phase.

For hospital beta-testing, thoroughly bench-tested and working beta versions of the IV pump were deployed in two hospital settings. The hospitals programmed drug libraries for at least 2 Clinical Care Areas. The devices were used for about 4 weeks. Surveys and interviews were conducted with the users to capture their “real world” experiences with the pump. Data from the pump usage and interaction memory was also analyzed and compared to original doctors’ orders. The beta tests revealed a number of opportunities to make improvements including revision of the more annoying alarm melodies, and revising the data entry methods for entering units of medication delivery time in hours or minutes.

Usability testing was also conducted on one of the sets of abbreviated instructions called TIPS cards. These cards serve as reminders for how to complete the most critical tasks. Numerous suggestions for improvement in the TIPS cards themselves as well as the user interface came from this work including: how to reset the “Air-in-Line” alarm and how to address the alarm and check all on screen Help Text for accuracy.

The abovementioned usability objectives were used as acceptance criteria for the validation usability tests. These objectives were met. For example, the calculated task completion accuracy was 99.66 percent for all tasks for first time nurse users with minimal training. There were a few minor usability problems uncovered that were subsequently fixed without major changes to the UI or that affected critical safety related tasks.

The risk analysis was iterated and revised as the product development matured. FMEAs were updated for safety critical risks associated with three product areas: the user interface, the mechanical and electrical subsystems and the product manufacturing process. Some detailed-implementation problems were found and fixed, but overall the risk of continuing into full-scale production, operations, and support was minimal. Systems engineering continued into the Operations phase, primarily to address customer change requests and problem reports, and to participate in planning for a broader product line of IV pumps.

Overall, customer satisfaction, sales, and profits from the SymbiqTM IV pump have been strong, and satisfaction levels from the management, financial, customer, end user, developer, maintainer, regulatory, and medical-community stakeholders have been quite high.

Summary

In summary, the SymbiqTM Medical Infusion Pump Case Study provides a successful example of the use of the systems engineering practices in the SEBoK. As appropriate for a next-generation, advanced technology product, it has a strong focus on Risk Management, but also illustrates the principles in Part 2 of synthesis, holism, dynamic behavior, adaptiveness, systems approach, progressive entropy reduction, and progressive stakeholder satisfying. It provides an example of an evolutionary and concurrent systems engineering process such as the Incremental Commitment Spiral Process, and of other Knowledge Areas in SEBoK Parts 3 and 4, including System Definition, System Realization, Systems Engineering Management, and Specialty Engineering.

References

Citations

Pew, R., and Mavor, A. 2007. Human-System Integration in the System Development Process, The National Academies Press.

Primary References

None

Additional References

None

Article Discussion

Signatures

--Hdavidz 00:37, 15 August 2011 (UTC)