Developing Systems Engineering Capabilities within Businesses and Enterprises

The pursuit of continuous improvement is a constant for many organsations. The (Morgan and Liker 2006) description of Toyota, the Lean principle of “pursue perfection” (Oppenheim et al 2010), and the (Kotter, 1995) principle of “don’t let up”, all drive a need for continuous improvement.

The ability to manage teams through their lifecycle - mobilize teams rapidly, establish and tailor an appropriate set of processes, metrics and systems engineering plans, support them to maintain a high level of performance, and capitalize acquired knowledge and redeploy the team members expeditiously as the team winds down - is a key organizational competence that has substantial leverage on project and organizational efficiency and effectiveness.

The business provides project teams with the necessary resource, background information, facilities, cash, support services, etc, and provides a physical, cultural and governance environment in which the projects and teams can be effective. So key functions of the parent organization include generating and maintaining relevant resources, allocating them to projects and teams, providing support and governance functions, maintaining expertise and knowledge (on process, application domain and solution technologies), securing the work in the first place, organizing finance, and maintaining the viability of the organization.

For improvements to really stick, they must reside in the organisation rather than the individuals, so the organsation can endure and not depend on some specific “heroes”. This is reflected in the CMMI progression from a "hero culture" to a "quantitatively managed and optimizing process" - though this process capability augments and does not replace individual talent.

This topic outlines the issues to be considered in capability development and organizational learning.

Overview

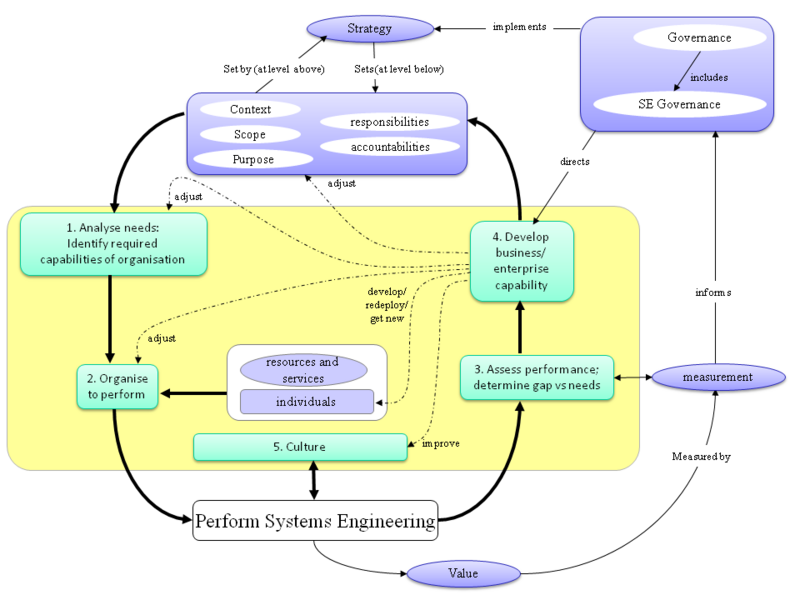

The following diagram (also presented in Enabling Businesses and Enterprises to Perform Systems Engineering) shows the "analyse - organize - perform - assess - develop" cycle used to structure this part of the SEBOK. This is essentially a reformulation of the Deming PDCA (Plan Do Check Act) cycle. The analysis step should cover both current and future needs, as far as these can be determined or predicted. Goals and performance assessment, as discussed in Assessing Systems Engineering Performance of Business and Enterprises, can be based on a number of evaluation frameworks, notably

- direct measures of business performance and effectiveness

- the CMMI capability maturity models.

There is evidence (SEI website) that many organizations find a positive correlation between business performance and CMMI levels.

Change Levers

SE managers have a number of possible change levers they can use to develop SE capabilities.

Different change levers have different time constants to take effect.

Adjust context, scope, purpose, responsibility, accountability of B/E

If the other change levers cannot achieve the desired effect, the business or enterprise may have to renegotiate its contribution to the higher level strategy and mission.

Review and adjust required capabilities

In the initial analysis, the needed capability may have been over- or under-estimated. Each time round the cycle, the need should be re-evaluated to make sure the planning assumptions are still valid.

Adjust organization within B/E

Adjusting organization and responsibilities so that "the right people are doing the right things" and making full use of their knowledge and skills, is often the easiest change to make and the one that may have the quickest effect.

A risk is that too much organizational churn disrupts relationships and can destabilize the organization and damage performance. CMMI Maturity levels and organizational quality approvals can be set back by ill-considered re-organization.

Develop/redeploy/get new resources, services and individuals

Resources, services and individuals may include any of the components of organizational SE capability listed in Organizing Business and Enterprises to Perform Systems Engineering.

Levers include subcontracting elements of the work, improving information flows, upgrading facilities, and launching short-term training and/or long term staff development programs.

Development of individuals is discussed in Enabling Individuals to Perform Systems Engineering.

Improve culture

Culture change is very important, very powerful, but needs to be handled as a long-term game and given long term commitment. (See Culture)

Adjust and improve alignment of measures and metrics

Measurement drives behaviour. "What gets measured gets done". Improving alignment of the goals and incentives of different parts of the organization so that everyone is working to a common purpose can be a very effective and powerful way of improving business and enterprise performance; it does require a top-down holistic approach, considering the business or enterprise as a system with a clear understanding of how the elements of enterprise capability interact to produce synergistic value. (See Assessing Systems Engineering Performance of Business and Enterprises)

It is commonly reported that as organizations move through CMMI levels the approach to metrics and measurement has to evolve. Measures that are important at high CMMI levels are meaningless or unavailable in less mature organizations.

Change methods

Doing everyday things better

There is a wealth of sources / techniques, including Kaizen, Deming PDCA (Deming 1994), Lean (Womack 1998, Oppenheim et al. 2010), 6-Sigma (Harry 1997), and CMMI (SEI 2010)

Value stream mapping is a powerful Lean technique to find ways to improve flow, and to improve handovers at interfaces.

Managing technology readiness

In high-technology industries, many problems are caused by attempting to transition new technologies into products and systems before the technology is mature, or to make insufficient allowance for the effort required to make the step from technology demonstration to reproducible and dependable performance in a product, or to overestimate the re-usability of an existing product. NASA's TRL (Technology Readiness Level) construct is widely and successfully used to understand and mitigate technology transition risk.

Planned change: standing up or formalizing SE in an organization

Planned change may include: introducing SE to a business (Farncombe et al 2009); improvement/transformation; formalizing the way a business or project does SE; dealing with a merger/demerger/major re-organization; developing a new generation or disruptive product, system, service or product line (Christensen 1997); entering a new market; and managing project lifecycle transitions: start-up, changing to the next phase of development, transition to manufacture/operation/support, wind down and decommissioning.

CMMI (SEI 2010) is widely used to provide a framework for planned change in a systems engineering context. Planned change needs to take a holistic approach considering people (knowledge, skills, culture, ability and motivation), process, measurement and tools as a coherent whole. It is now widely believed that tools and process are not a substitute for skills and experience but merely provide a framework in which skilled and motivated people can be more effective. So change should start with people not with tools. Before a change is started it is advisable to baseline the current business performance and systems engineering capability, and establish metrics that will show early on whether the change is achieving the desired effect and benefits.

Responding to unforeseen disruption

Unforeseen disruptions may be externally or externally imposed. Externally imposed disruptions may be caused: by the customer - win/lose contract, mandated teaming or redirection; by competitors - current offering becomes less/more competitive, a disruptive innovation may be launched in market; or by Governance and regulatory changes - new processes, certification, safety or environmental standards. Internal or self-induced disruptions may include: a capability drop-out due to loss of people, facilities, financing; product or service failure in operation or disposal; strategy change e.g. new CEO, respond to market dynamics; or a priority over-ride.

Embedding change

In a Systems Engineering context, sustained effort is required to maintain improvements such as higher CMMI levels, Lean and Safety cultures, etc, once they are achieved. There are several useful change models, including Kotter’s 8 phases of change (Kotter 1995): establish a sense of urgency, create a coalition, develop a clear vision, share the vision, empower people to clear obstacles, secure short term wins, consolidate and keep moving, and anchor the change. The first six steps are the easy ones. The Chaos Model (Zuijderhoudt 1990, 2002) draws on complexity theory to show that regression is likely if the short term wins are not consolidated, institutionalized and anchored. This explains the oft-seen phenomenon of organizations indulging in numerous change initiatives, none of which sticks because attention moves on to the next before the previous one is anchored.

A structured survey of improvement and change literature relevant to SE in businesses and enterpises

SE leaders (Directors, functional managers, team leaders and specialists) have responsibilities, and control levers to implement them, that vary depending on their organization’s business model and structure. A great deal of their time and energy is spent managing change in pursuit of short, medium and long term organizational goals: “doing everyday things better”; making change happen, embedding change and delivering the benefit; and coping with the effects of disruptions. Mergers, acquisitions and project start-ups, phase changes, transitions from “discovery” to “delivery” phase, transition to operation, sudden change in level of funding, can all impose abrupt changes on organizations that can destabilize teams, processes, culture and performance. The table below provides links to both the general management literature and specific systems engineering knowledge.

| Area | Primary “business” references | Primary SE references |

| Doing every day things better | Kaizen; Lean (Womack); 6-Sigma (Harry, 1997)

4 competencies of Learning Organisation – absorb, diffuse, generate, exploit (Sprenger & Ten Have, 1996) Covey’s 7 habits of very effective people (Covey, 1989, 2004) |

CMMI

Forsberg & Mooz, Visualizing project management (Forsberg & Mooz, 2005) INCOSE IEWG "Conops for a Systems Engineeriing Educational Community", Ring et al, 2004) INCOSE Lean Enablers for SE (Oppenhein et al, 2010) |

| Dealing with unplanned disruption | Mitroff, managing crises before they happen (Mitroff & Anagnos, 2005);

Shell, Scenario Planning (Wack, 1985; Ringland, 1988) |

Scott Jackson, architecting resilient systems (Jackson, 2010)

Design principles for ultra-large-scale systems (Sillitto 2010 and 2011) |

| Driving disruptive innovation | Christensen’s Innovator’s Dilemma (Christensen, 1997)

Mintzberg “Rise and fall of strategic planning”, (Mintzberg, 2000) BS7000, Standard for innovation management (BSI, 2008) |

|

| Exploiting unexpected opportunities | Mintzberg, rise and fall of strategic planning (Mintzberg, 2000)

Mission Command (military), Auftragstechnik (described in Bungay, 2002, from page 32) |

Architecting for Flexibility and Resilience (Jackson, 2010)

Open system architectures; Lean SE; (Oppenheim et al, 2010) Agile methodologies |

| Implementing and embedding planned change | Kotter’s 8 phases of change (Kotter, 1995),

Berenschot’s 7 forces (Berenschot, 1991) Levers of control (Simon 1995) – tension between control, creativity, initiative and risk taking Chaos model, “complexity theory applied to change processes in organisations”; (Zuiderhoudt et al, 1999) Business Process Re-engineering (Hammer & Champy, 1993) Senge’s 5th discipline (Senge, 1990, 2006) Change Quadrants (Amsterdam, 1999) |

"Doing it differently - systems for rethinking construction" (Blockley & Godfrey, 2000)

INCOSE UK Chapter Z-guides:

|

| Understanding peoples’ motivation, behaviour | Maslow’s hierarchy of needs

Myers-Briggs Type Indicator; NLP (Neuro-Linguistic Programming) (See for example Knight, 1995-2009) Socio-technical organisation (Taylor & Felton, 1993) Core quadrants, (Offman, 1992, 2001) |

INCOSE Intelligent Enterprise Working Group – “enthusiasm”, stretch goals (Ring et al, 2004)

Sommerville, Socio Technical Systems Engineering, Responsibility Mapping (Sommerville et al, ) |

| Understanding culture | Hofstede, Cultural Dimensions, (Hofstede, 1966 - -)

Etzioni, Compliance Typology (Etzione, ) |

|

| Helping individuals cope with change | 5 C’s of individual change, and Rational/emotional axes, Kets De Vries, quoted in “key management models” (Ten Have et al, 2003) | Relationships made easy, Fraser, 2010 – rational/emotional, NLP and other methods |

References

Citations

- Bungay, Steven, "Alamein". Aurum press, 1st published 2002, paperback edition 2003

- Christensen, C. 1997. The Innovator's Dilemma: When New Technologies Cause Great Firms to Fail. Harvard Business School Press.

- Deming, W.E. 1994. The New Economics. Massachusetts Institute of Technology, Centre for Advanced Educational Services, Cambridge, MA.

- Hammer, M. and Champy, J. A.: (1993) Reengineering the Corporation: A Manifesto for Business Revolution, Harper Business Books, New York, 1993.

- Harry, M.J. 1997. The Nature of Six Sigma Quality. Motorola University Press, Schaumburg, IL.

- Farncombe et al, INCOSE UK Chapter, Z-2 Guide, Issue 2.0, March 2009, "Enabling systems engineering"

- Godfrey et al, INCOSE UK Chapter, Z-7 Guide, Issue 1.0, March 2010, "Systems Thinking",

- Knight, Sue, "NLP at work - Neuro Linguistic Programming - the essence of excellence", 1st edition 1995, 3rd edition published by Nicholas Brealey Publishing, London and Boston, 2005)

- Kotter, J. 1995. Leading Change: Why Transformation Efforts Fail. Harvard Business Review, March–April 1995.

- Morgan, J. and J. Liker, J. 2006. The Toyota Product Development System: Integrating People, Process and Technology. Productivity Press.

- Oppenheim et al. 2010, INCOSE Lean SE WG. “Lean enablers for Systems Engineering”, accessible at http://cse.lmu.edu/about/graduateeducation/systemsengineering/INCOSE.htm.

- Simons, R., 1995. Levers of Control, How Managers Use Innovative Control Systems to Drive Strategic Renewal. Harvard Business School Press, Boston, MA.

- Sillitto, H, 2010 - "Design principles for ultra-large scale systems", Proceedings of INCOSE International Symposium, Chicago, July 2010, reprinted in The Singapore Engineer, IES, April 2011

- Ten Have, S; Ten Have, W; Stevens, Frans, and van der Elst, Marcel; "Key management models - the management tools and practices that will improve your business", FT Prentice Hall, Pearson Education Ltd, 2003

- Womack, J and Jones, D, 1998, “Lean Thinking”, Simon Schuster, New York

- Zuiderhoudt, Wobben, Ten Have, Busato, “complexity theory applied to change processes in organisations”; 1999

Primary References

All primary references should be listed in alphabetical order. Remember to identify primary references by creating an internal link using the ‘’’reference title only’’’ (title). Please do not include version numbers in the links.

Additional References

All additional references should be listed in alphabetical order.

Article Discussion

(H Davidz, 8/16)

- Table 1 references need to be fully populated

- This topic might focus more on developing SE-specific capabilities within businesses and enterprises.

- This is the section where we might talk about big picture major SE workforce overhauls. For example, in the face of a trend of SE failures, perhaps the enterprise initiates an aggressive SE overhaul. As with NASA SE, perhaps the enterprise overhauls the entire SE function starting with a new core procedural requirement, followed by an SE handbook and SE leadership program.

- A broader range of ways to develop SE-specific capabilities could be discussed. For example, a company might begin a strategic partnership with a university for a corporate SE education program. Changes in incentives could be adopted. Perhaps new SE tools could be utilized by the business or enterprise. An enterprise could choose to keep two contractors engaged to develop systems skills for both. Perhaps acquisition cycles could be altered, with shorter life cycles giving more employees a chance to see requirements realized in an operational system. This topic could expand the SE capability interventions from the individual and team levels to the business and enterprise levels.