Difference between revisions of "Product Systems Engineering Background"

m (Text replacement - "SEBoK v. 2.9, released 13 November 2023" to "SEBoK v. 2.9, released 20 November 2023") |

|||

| (128 intermediate revisions by 12 users not shown) | |||

| Line 1: | Line 1: | ||

| − | == | + | ---- |

| + | '''''Lead Author:''''' ''Ricardo Pineda'' | ||

| + | ---- | ||

| + | [[File:PPI.png|thumb|250px|right|<center>The "Product Systems Engineering" knowledge area is graciously sponsored by PPI.<center>]] | ||

| + | == Product Types == | ||

| + | A {{Term|System (glossary)|system}} is by definition composed of elements that interact. The system itself is usually an element of a larger system, and each element can often also be viewed as a system on its own. | ||

| − | + | A {{Term|System Element (glossary)|system element}} consists of one or more products. Products need to be produced or acquired. Some can be acquired or procured as-is, without need for fabrication or modification. Others need to be engineered, and in some cases, systems-engineered (Martin 1997). Basic product types are depicted in the figure below. | |

| − | |||

| − | |||

| − | |||

| − | + | Types of products are not limited to hardware or software. Many other types of products perform functions necessary to meet stakeholder needs. Some are only relevant to certain industries or domains, such as structures for civil engineering, or ships for shipping or the naval domain. Systems engineers must remember not to allocate the required behavior for a system to hardware and software elements alone. | |

| − | + | While we may associate the idea of a product with concrete objects like computer chip, phones, aircraft, or even command, control and communications centers, an organization or a process can also be a product. Sometimes a product is not complex enough to justify performing Product SE, and only needs product design engineering. Enterprise SE and Service SE should determine whether a product needs Product SE. | |

| − | + | ===Product Taxonomy=== | |

| − | |||

| − | + | For any system being developed, the systems engineers must decide what are the right elements to be included. This is not self-evident, because basic product types are not necessarily mutually exclusive. For example, some would consider that facilities contain hardware and people. Others would consider facilities to be separate from hardware and people. Some would include material as part of hardware, while others would not. Creating a taxonomy of product types can help the systems engineer think clearly and thoroughly about what components to include. | |

| − | + | == Business Objectives and Products == | |

| − | + | When it develops and launches a new product, an enterprise must align that product with its business goals, internal capabilities, and competition. It must align the end product with the systems expected to realize and sustain it. | |

| − | + | The new product concept must be based on analysis that, besides product potential, also explores the ability of the enterprise to exploit that potential, including factors like organizational culture, focus, goals, and processes. Present and future markets and technology must be analyzed. So must several dimensions of competition: competitors’ offerings and their plans, for entry into new markets and for product expansion including new functionality, features, or services. These, and the ability of the enterprise to react to them, must also be monitored for the enterprise to remain competitive in the long term. | |

| − | + | Accelerating economic globalization since the 1970s has forced enterprises to respond to global needs, not just local or regional ones. Enterprises in the resulting hyper-competitive business environment must analyze their financial goals, their market positions, and the business segments in which they participate, in order to understand what products are required. | |

| − | + | This is true for completely new products , product enhancements, penetration of new markets, and growth within existing markets. | |

| − | + | == Relationship between Product Systems Engineering and Product Development == | |

| − | + | Product development is the process of bringing a new product to market. Product SE (PSE) considers the complete product system–that is the product in the context of all its enabling elements. PSE takes a full life cycle perspective, “from cradle to grave” or “dust to dust.” | |

| − | + | Technology-based product development may be thought of as coming from two sources. One, where innovation enhances existing technology, is aimed at relatively short-term market windows. The other involves long-term research to identify the technology developments required to realize the concept. These may be technologies whose availability is not foreseen in the near future, meaning that substantial investment and long lead times may be required before the proof of concept, initial operational capabilities (IOCs) or prototyping stages are reached, let alone the commitment to realize the actual product offering. Some authors claim that the systems engineering process and the new product development (NPD) process for this second source are one and the same. | |

| − | + | It is from the second source that strategic initiatives (long-term applied research) realize new products in areas like military aircraft or bioengineering. When research resolves fundamental questions on matters of science or national/regional interest technology, breakthroughs occur. | |

| − | + | This article concentrates on the first source of technology-based product development, that is, the one driven by ever-evolving market needs to enhance existing technology. | |

| − | + | ===Product Development Patterns=== | |

| − | + | When existing or near-future technology innovations are exploited to generate new product ideas, product development may follow any one of following scenarios (Phillips 2001): | |

| − | + | *Product development may use well-established technologies to help the enterprise improve the efficiency of current operations. | |

| + | *Product development may use well-established technologies to help the enterprise into new kinds of operations. | ||

| + | *Product development may use leading edge technologies to improve the efficiency of current operations. | ||

| + | *Product development may use leading edge technologies to help the enterprise into new kinds of operations. | ||

| − | + | The product itself may simply be a modification of an existing product or its presentation, it may possess new or different characteristics that offer additional benefits to the customer, and/or it may be entirely new and satisfy a newly-defined customer want or market niche ([http://www.businessdictionary.com/definition/product-development.html http://www.businessdictionary.com/definition/product-development.html]). | |

| − | + | Existing realization or sustainment systems may not be adequate to develop a given product. For example, it might be necessary to change development practices, use different testing methods or facilities, or upgrade manufacturing equipment and procedures. There might need to be improved customer support procedures and newly trained support personnel, upgraded maintenance facilities and tools, or modified spare parts delivery techniques. | |

| − | + | ===Market Pressures=== | |

| − | + | The product development process must be dynamic, adaptive, and competitive on cost, time-to-market, performance, and quality on a global scale. This is because in the global economy continuous technology innovation and constantly evolving markets and customer needs demand a rapid response. | |

| − | + | Products themselves are often multidisciplinary in nature; product development must have close participation, not only from the different specialty engineering fields (mechanical, electrical, industrial, materials, and so on), but also from the finance field to analyze the total cost of development (including production), marketing and sales to understand market behavior and acceptance, manufacturers and distributors, and legal and public relations experts. | |

| − | The | + | All this has mandated enterprises to assess how they create their products and services. The result has been an effort to streamline the development process. One example of this is seen by the deployment of integrated product teams (IPTs) sometimes known as integrated product development teams (IPDTs). |

| − | + | ===Product Systems Engineering=== | |

| − | + | Product systems engineering strives for the efficient use of company resources in order to achieve business objectives and deliver a quality product. Product systems engineering activities range from concept to analysis to design and determine how conceptual and physical factors can be altered to manufacture the most cost-effective, environmentally friendly product that satisfies customer requirements. Engineering the product system requires an interdisciplinary approach that includes an analysis of the product and its related elements such as manufacturing, maintenance, support, logistics, phase-out, and disposal; these are all activities which belong to either the realization system or the sustainment system. The proper application of systems engineering and analysis ensures the timely and balanced use of human, financial, and technological assets, and technology investments to minimize problems, harmonize overall results, and maximize customer satisfaction and company profits. | |

| − | + | Products are as diverse as the customers that acquire them and there are no universally accepted methods, processes, and technologies (MPTs) for end-to-end analysis of products and their supporting subsystems. Every product needs to adapt existing MPTs based on prior experiences and best practices, such as Toyota (Hitchens 2007), MITRE (Trudeau 2010), and NASA (NASA SELDP 2011). Product systems engineering helps develop the end-to-end analysis of products and sub-systems by performing the following tasks: | |

| − | + | * determining the overall scope of needs for the product system; | |

| + | * defining product and system requirements; | ||

| + | * considering all interactions between the different elements of the product system; | ||

| + | * organizing and integrating engineering disciplines; and | ||

| + | * establishing a disciplined approach that includes review, evaluation and feedback, and ensures orderly and efficient progress. | ||

| − | + | Constantly evolving needs and requirements, along with constant technology innovations, may render a committed product development obsolete even before deployment. This has led to debate among systems engineering professionals on the need for the systems engineering process to become more rapidly adaptable. Platform-based solutions to resolve some of these challenges (infrastructure as a service, platform as a service, and software as a service) are being studied and proposed (MITRE 2010; Boehm 2010). | |

| − | + | ===Integrated Product Development Process=== | |

| − | + | The integrated product development process (IPDP) starts with understanding market needs and developing a strategy that creates products that satisfy or exceed customer expectations, respond to evolving customer demands, adapt to changing business environments, and incorporate systems thinking to generate novel ideas and co-create value with extensive stakeholders’ participation. IPDP is a continuously evolving process that strives to realize products whose cost, performance, features, and time-to-market help increase company profitability and market share. Magrab, et al. (2010) discussed the IPDP in terms of four different stages; Figure 1 provides a snapshot of an IPDP and the main tasks carried out at each stage. | |

| − | + | ====Stage I: Product Identification==== | |

| − | + | During the product identification stage, the enterprise aims to identify an enterprise-wide strategy that flows down to individual product strategies resulting in a good business investment for the company. During this stage addressable markets for the product are identified in addition to geographical coverage of the product. The developments through this stage result in demonstration of strong customer need, determination of potential markets and geographic scope, the fitness of enterprise core capabilities to the product strategy, business profitability (return on investment, profit & loss), etc. | |

| − | The | + | During this stage an integrated product team (IPT) first develops the IPDP for the project, usually by tailoring a corporate IPDP standard. The IPT assesses required technology innovation, feasibility of existing technologies, estimated time and cost of technology development, and the risks associated with markets, finances and technologies risk, etc. This stage also takes into account inputs from the continuous improvement (CI) process to develop new features and enhancements in existing products to address new market needs or customer demands. |

| − | + | ====Stage II: Concept Development==== | |

| − | + | The main goal of the Concept Development stage is to generate feasible concepts for the potential product and develop MPTs that will satisfy the product’s performance goals of economic viability and customer satisfaction. These concept designs must ensure that the company’s core competencies can satisfy the requirements to produce the products while taking into account the market viability, manufacturability, and technical feasibility through an extensive analysis of alternative process. | |

| − | + | During this stage SE supports the IPT in identifying different operational scenarios and modes of operation, functional requirements of the products, technology and performance risks, and the main components of the products and required interfaces among them, etc. This stage involves a highly interactive and iterative exchange of concepts among several IPTs and, depending on complexity of the products, a Systems Engineering Integration Team may be required to ensure analysis of all the possible solutions. During this stage inputs from the CI process helps analyze new technologies/processes including upgrades to existing technologies and create products that result in enhanced customer experiences. | |

| − | + | ====Stage III: Design and Manufacturing==== | |

| − | + | During the design and manufacturing stage the actual product is realized and manufactured. This stage starts with creating engineering drawings for the product, product configuration items specs, "design for X" (DFX), manufacturing design plans, production plans and schedules, test production run to ensure that the product meets customer requirements and quality criteria, and a plan for full production, logistics and distribution. | |

| − | During this stage | + | During this stage the product design & manufacturing engineering team works closely with operations managers to create MPTs to manage the technical effort for the product from an end-to-end perspective. Some of the SE activities during this stage include product integration, verification and validation plans; modeling, simulation, test & evaluation of the product system under critical scenarios; launch readiness plans including end-user test plans, operational readiness, etc. During this stage MPTs are developed and documented for proper handling of defective parts, processes, or functionalities. The CI process inputs include product and process performance enhancements and sustained life-cycle operations support. |

| − | + | ====Stage IV: Product Launch==== | |

| − | + | During the product launch stage, the product is delivered to its potential markets. During production and deployment, MPTs are developed to ensure that the product meets its quality goals, satisfies customer requirements, and realizes the business plan goals. This requires provisions for customer care, logistics, maintenance, training etc., and a CI process to monitor product and product system technical performance and product quality. The CI process is realized through extensive data collection using customer satisfaction surveys and remotely or manually observing, recording, and analyzing process performance metrics, technical performance measure, quality metrics, etc. | |

| − | + | [[File:IPDP PSE Background Figure 1.png|600px|thumb|center|'''Figure 1. Integrated Product Development Process.''' (SEBoK Original)]] | |

| − | + | ==Relationship between Product Systems Engineering and Technology Development== | |

| − | + | As technological advancement accelerates, product life cycles become shorter, especially for high technology products. As a result, enterprises risk having outdated or obsolete products that have lost pace with markets trends, technology trends, or customer expectations. | |

| − | + | Product systems engineering should bring awareness of technology changes and trends to the analysis of new product ideas or innovations. This affects the time and cost inputs into the technical feasibility analysis of the product. The result should include a road map of required technology developments, which is then used to create the overall road map for the new product offering. | |

| + | In these cases, new product ideas impose requirements on new technology developments. | ||

| + | On the other hand, when technology developments or breakthroughs drive product innovation or the generation of new markets, the technology developments may also generate requirements on product features and functionalities. Factors which dictate decisions about introducing products include the technology readiness levels (TRL), the integration readiness levels (IRL), the manufacturing readiness levels (MRL), the system readiness levels (SRL), and the operational readiness of the enterprise to launch the product system. See the "Readiness Levels" section in the [[Product Systems Engineering Special Activities]] article. | ||

| − | + | Understanding the entities (i.e., components or elements) that compose the product is not a trivial task for systems engineers. It is not unusual for a new product to require developments in several technologies, including new materials, electronic components, software, maintenance and repair procedures, processes, or organizational structures. All of these developments must be factored into the IPDP for the successful deployment and proper use of the product. | |

| − | + | [[File:PSE_PSEB_Fig2.png|650px|thumb|center|'''Figure 2. Basic Product Types that Constitute a Product System (Martin 1997).''' This material is reproduced with permission of John Wiley & Sons, Inc. All other rights are reserved by the copyright owner.]] | |

| − | + | ==Product Type Examples== | |

| − | + | Examples of each product type are shown below (Martin 1997). | |

| − | + | {| | |

| + | |+'''Table 1. Product Types (Martin 1997).''' This material is reproduced with permission of John Wiley & Sons, Inc. | ||

| + | !Type | ||

| + | !Examples | ||

| + | |- | ||

| + | |'''Hardware''' | ||

| + | |Computer processor unit, radar transmitter, satellite payload, telephone, diesel engine, data storage device, network router, airplane landing gear | ||

| + | |- | ||

| + | |'''Software''' | ||

| + | |Computer operating system, firmware, satellite control algorithm, robot control code, telephone switching software, database application | ||

| + | |- | ||

| + | |'''Personnel''' | ||

| + | |Astronaut, computer operator, clerk, business executive, Laika (the cosmonaut dog), bus driver, cashier, maintenance technician | ||

| + | |- | ||

| + | |'''Facilities''' | ||

| + | |Space rocket launch pad, warehouse building, shipping docks, airport runway, railroad tracks, conference room, traffic tunnel, bridge, local area network cables | ||

| + | |- | ||

| + | |'''Data''' | ||

| + | |Personnel records, satellite telemetry data, command and control instructions, customer satisfaction scores | ||

| + | |- | ||

| + | |'''Materials''' | ||

| + | |Graphite composite, paper, gold, concrete, stone, fiberglass, radar absorption material, cladded metals, integrated circuit substrate, magnetic memory core | ||

| + | |- | ||

| + | |'''Media''' | ||

| + | |Data storage media (tape, disc, memory card), signal transport media (twisted pair wire, fiber optic cable, RF spectrum), communications media (television, radio, magazines), social media (blogs, Twitter, Facebook) | ||

| + | |- | ||

| + | |'''Techniques''' | ||

| + | |Soldering, trouble trick response process, change notice handling, telephone answering protocol, project scheduling, data sorting algorithm | ||

| + | |} | ||

| − | + | Materials could be thought of as basic raw materials, like steel, or as complex materials, like cladded metals, graphite composites, or building aggregate material. Personnel are not normally thought of as a “product,” but that can change depending on the type of system in question. The National Aeronautics and Space Administration (NASA) space program “system” certainly produces astronauts. When personnel are considered product(s), it is not usually possible to simply find and hire personnel with the requisite knowledge, skills, and experience. These personnel “products” can often be developed using a product SE approach (Martin 1996). For example, you could specify requirements (i.e., required knowledge, skills, and experience) for each person that is part of the system. Interfaces can be specified for each person, and an assessment can be made as to the maturity of each person (i.e., each potential product). These are a few examples of how product SE can be applied to personnel products. | |

| − | + | In enterprise systems engineering, we may need education and training systems to make up a part of our personnel system in order to produce people with the right competencies and capabilities. | |

| − | + | ==References== | |

| − | + | ===Works Cited=== | |

| + | Academy of Program/Project and Engineering Leadership (APPEL). 2009. ''NASA's Systems Engineering Competencies''. Washington, D.C., USA: US National Aeronautics and Space Association. Available at: [http://www.nasa.gov/offices/oce/appel/pm-development/pm_se_competency_framework.html http://www.nasa.gov/offices/oce/appel/pm-development/pm_se_competency_framework.html]. | ||

| − | '' | + | Blanchard, B.S., and W.J. Fabrycky. 2011. ''Systems Engineering and Analysis'', 5th ed. Prentice Hall International Series in Industrial and Systems Engineering. Englewood Cliffs, NJ, USA: Prentice Hall. |

| − | + | Boehm, B. 2010. ''Systems 2020 Strategic Initiative''. Hoboken, NJ, USA: Systems Engineering Research Center (SERC), SERC-2010-TR-009. | |

| − | + | Grady, J. 2010. ''[[Systems Synthesis]] - Product and Process Design''. Boca Raton, FL, USA: CRC Press. | |

| − | + | INCOSE. 2012. ''[[INCOSE Systems Engineering Handbook|Systems Engineering Handbook]]: A Guide for System Life Cycle Processes and Activities'', version 3.2.2. San Diego, CA, USA: International Council on Systems Engineering (INCOSE), INCOSE-TP-2003-002-03.2.2. | |

| − | + | Magrab, E., S. Gupta, P. McCluskey, and P. Sandborn. 2010. ''[[Integrated Product and Process Design and Development]] - The Product Realization Process''. Boca Raton, FL, USA: CRC Press. | |

| − | '' | + | Martin, J.N. 1997. ''[[Systems Engineering Guidebook]]: A process for developing systems and products'', 1st ed. Boca Raton, FL, USA: CRC Press. |

| − | + | MITRE. 2010. ''Platform as a Service: A 2010 Marketplace Analysis'', Cloud Computing Series. Bedford, MA, USA: Systems Engineering at MITRE. | |

| + | Morse, L., and D. Babcock. 2007. ''Managing Engineering and Technology'', 4th ed. Upper Saddle River, NJ, USA: Prentice Hall. | ||

| + | Phillips, F. 2001. ''Market Oriented Technology Management: Innovating for Profit in Entrepreneurial Times''. New York, NY, USA: Springer. | ||

| − | + | Trudeau, P.N. 2010. ''Designing and Enhancing a Systems Engineering Training and Development Program''. Bedford, MA, USA: The MITRE Corporation. | |

| − | + | Wasson, C.S. 2006. ''System Analysis, Design, and Development''. New York, NY, USA: John Wiley & Sons. | |

| − | + | ===Primary References=== | |

| − | |||

| − | ==References== | ||

| − | + | Grady, J. 2010. ''[[Systems Synthesis]] - Product and Process Design''. Boca Raton, FL, USA: CRC Press. | |

| − | |||

| − | + | Magrab, E., S. Gupta, P. McCluskey, and P. Sandborn. 2010. ''[[Integrated Product and Process Design and Development]] - The Product Realization Process''. Boca Raton, FL, USA: CRC Press. | |

| − | + | Martin, J.N. 1997. ''[[Systems Engineering Guidebook]]: A process for developing systems and product'', 1st ed. Boca Raton, FL, USA: CRC Press. | |

| − | + | ===Additional References=== | |

| + | Academy of Program/Project and Engineering Leadership (APPEL). 2009. ''NASA's Systems Engineering Competencies''. Washington, D.C., USA: US National Aeronautics and Space Association. Available at: [http://www.nasa.gov/offices/oce/appel/pm-development/pm_se_competency_framework.html http://www.nasa.gov/offices/oce/appel/pm-development/pm_se_competency_framework.html]. | ||

| − | + | Blanchard, B.S., and W.J. Fabrycky. 2011. ''Systems Engineering and Analysis'', 5th ed. Prentice Hall International Series in Industrial and Systems Engineering. Englewood Cliffs, NJ, USA: Prentice Hall. | |

| − | + | Boehm, B. 2010. ''Systems 2020 Strategic Initiative''. Hoboken, NJ, USA: Systems Engineering Research Center (SERC), SERC-2010-TR-009. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | INCOSE, Systems Engineering | + | INCOSE. 2012. ''[[INCOSE Systems Engineering Handbook|Systems Engineering Handbook]]: A Guide for System Life Cycle Processes and Activities'', version 3.2.2. San Diego, CA, USA: International Council on Systems Engineering (INCOSE), INCOSE-TP-2003-002-03.2.2. |

| − | + | MITRE. 2010. ''Platform as a Service: A 2010 Marketplace Analysis'', Cloud Computing Series. Bedford, MA, USA: Systems Engineering at MITRE. | |

| − | + | Morse, L., and D. Babcock. 2007. ''Managing Engineering and Technology'', 4th ed. Upper Saddle River, NJ, USA: Prentice Hall. | |

| − | + | Phillips, F. 2001. ''Market Oriented Technology Management: Innovating for Profit in Entrepreneurial Times''. New York, NY, USA: Springer. | |

| − | + | Trudeau, P.N. 2010. ''Designing and Enhancing a Systems Engineering Training and Development Program''. Bedford, MA, USA: The MITRE Corporation. | |

| − | + | Wasson, C.S. 2006. ''System Analysis, Design, and Development''. New York, NY, USA: John Wiley & Sons. | |

| − | + | ---- | |

| − | + | <center>[[Product Systems Engineering|< Previous Article]] | [[Product Systems Engineering|Parent Article]] | [[Product as a System Fundamentals|Next Article >]]</center> | |

| + | <center>'''SEBoK v. 2.9, released 20 November 2023'''</center> | ||

| − | [[Category:Part | + | [[Category:Part 4]][[Category:Topic]] |

| + | [[Category:Product Systems Engineering]] | ||

Latest revision as of 23:57, 18 November 2023

Lead Author: Ricardo Pineda

Product Types

A system is by definition composed of elements that interact. The system itself is usually an element of a larger system, and each element can often also be viewed as a system on its own.

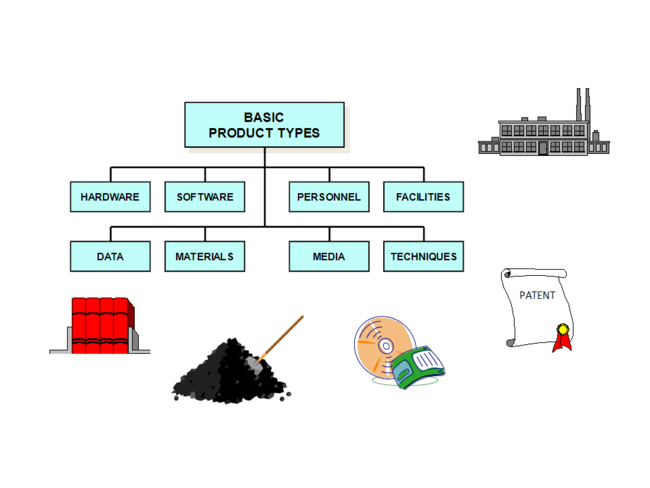

A system element consists of one or more products. Products need to be produced or acquired. Some can be acquired or procured as-is, without need for fabrication or modification. Others need to be engineered, and in some cases, systems-engineered (Martin 1997). Basic product types are depicted in the figure below.

Types of products are not limited to hardware or software. Many other types of products perform functions necessary to meet stakeholder needs. Some are only relevant to certain industries or domains, such as structures for civil engineering, or ships for shipping or the naval domain. Systems engineers must remember not to allocate the required behavior for a system to hardware and software elements alone.

While we may associate the idea of a product with concrete objects like computer chip, phones, aircraft, or even command, control and communications centers, an organization or a process can also be a product. Sometimes a product is not complex enough to justify performing Product SE, and only needs product design engineering. Enterprise SE and Service SE should determine whether a product needs Product SE.

Product Taxonomy

For any system being developed, the systems engineers must decide what are the right elements to be included. This is not self-evident, because basic product types are not necessarily mutually exclusive. For example, some would consider that facilities contain hardware and people. Others would consider facilities to be separate from hardware and people. Some would include material as part of hardware, while others would not. Creating a taxonomy of product types can help the systems engineer think clearly and thoroughly about what components to include.

Business Objectives and Products

When it develops and launches a new product, an enterprise must align that product with its business goals, internal capabilities, and competition. It must align the end product with the systems expected to realize and sustain it.

The new product concept must be based on analysis that, besides product potential, also explores the ability of the enterprise to exploit that potential, including factors like organizational culture, focus, goals, and processes. Present and future markets and technology must be analyzed. So must several dimensions of competition: competitors’ offerings and their plans, for entry into new markets and for product expansion including new functionality, features, or services. These, and the ability of the enterprise to react to them, must also be monitored for the enterprise to remain competitive in the long term.

Accelerating economic globalization since the 1970s has forced enterprises to respond to global needs, not just local or regional ones. Enterprises in the resulting hyper-competitive business environment must analyze their financial goals, their market positions, and the business segments in which they participate, in order to understand what products are required.

This is true for completely new products , product enhancements, penetration of new markets, and growth within existing markets.

Relationship between Product Systems Engineering and Product Development

Product development is the process of bringing a new product to market. Product SE (PSE) considers the complete product system–that is the product in the context of all its enabling elements. PSE takes a full life cycle perspective, “from cradle to grave” or “dust to dust.”

Technology-based product development may be thought of as coming from two sources. One, where innovation enhances existing technology, is aimed at relatively short-term market windows. The other involves long-term research to identify the technology developments required to realize the concept. These may be technologies whose availability is not foreseen in the near future, meaning that substantial investment and long lead times may be required before the proof of concept, initial operational capabilities (IOCs) or prototyping stages are reached, let alone the commitment to realize the actual product offering. Some authors claim that the systems engineering process and the new product development (NPD) process for this second source are one and the same.

It is from the second source that strategic initiatives (long-term applied research) realize new products in areas like military aircraft or bioengineering. When research resolves fundamental questions on matters of science or national/regional interest technology, breakthroughs occur.

This article concentrates on the first source of technology-based product development, that is, the one driven by ever-evolving market needs to enhance existing technology.

Product Development Patterns

When existing or near-future technology innovations are exploited to generate new product ideas, product development may follow any one of following scenarios (Phillips 2001):

- Product development may use well-established technologies to help the enterprise improve the efficiency of current operations.

- Product development may use well-established technologies to help the enterprise into new kinds of operations.

- Product development may use leading edge technologies to improve the efficiency of current operations.

- Product development may use leading edge technologies to help the enterprise into new kinds of operations.

The product itself may simply be a modification of an existing product or its presentation, it may possess new or different characteristics that offer additional benefits to the customer, and/or it may be entirely new and satisfy a newly-defined customer want or market niche (http://www.businessdictionary.com/definition/product-development.html).

Existing realization or sustainment systems may not be adequate to develop a given product. For example, it might be necessary to change development practices, use different testing methods or facilities, or upgrade manufacturing equipment and procedures. There might need to be improved customer support procedures and newly trained support personnel, upgraded maintenance facilities and tools, or modified spare parts delivery techniques.

Market Pressures

The product development process must be dynamic, adaptive, and competitive on cost, time-to-market, performance, and quality on a global scale. This is because in the global economy continuous technology innovation and constantly evolving markets and customer needs demand a rapid response.

Products themselves are often multidisciplinary in nature; product development must have close participation, not only from the different specialty engineering fields (mechanical, electrical, industrial, materials, and so on), but also from the finance field to analyze the total cost of development (including production), marketing and sales to understand market behavior and acceptance, manufacturers and distributors, and legal and public relations experts.

All this has mandated enterprises to assess how they create their products and services. The result has been an effort to streamline the development process. One example of this is seen by the deployment of integrated product teams (IPTs) sometimes known as integrated product development teams (IPDTs).

Product Systems Engineering

Product systems engineering strives for the efficient use of company resources in order to achieve business objectives and deliver a quality product. Product systems engineering activities range from concept to analysis to design and determine how conceptual and physical factors can be altered to manufacture the most cost-effective, environmentally friendly product that satisfies customer requirements. Engineering the product system requires an interdisciplinary approach that includes an analysis of the product and its related elements such as manufacturing, maintenance, support, logistics, phase-out, and disposal; these are all activities which belong to either the realization system or the sustainment system. The proper application of systems engineering and analysis ensures the timely and balanced use of human, financial, and technological assets, and technology investments to minimize problems, harmonize overall results, and maximize customer satisfaction and company profits.

Products are as diverse as the customers that acquire them and there are no universally accepted methods, processes, and technologies (MPTs) for end-to-end analysis of products and their supporting subsystems. Every product needs to adapt existing MPTs based on prior experiences and best practices, such as Toyota (Hitchens 2007), MITRE (Trudeau 2010), and NASA (NASA SELDP 2011). Product systems engineering helps develop the end-to-end analysis of products and sub-systems by performing the following tasks:

- determining the overall scope of needs for the product system;

- defining product and system requirements;

- considering all interactions between the different elements of the product system;

- organizing and integrating engineering disciplines; and

- establishing a disciplined approach that includes review, evaluation and feedback, and ensures orderly and efficient progress.

Constantly evolving needs and requirements, along with constant technology innovations, may render a committed product development obsolete even before deployment. This has led to debate among systems engineering professionals on the need for the systems engineering process to become more rapidly adaptable. Platform-based solutions to resolve some of these challenges (infrastructure as a service, platform as a service, and software as a service) are being studied and proposed (MITRE 2010; Boehm 2010).

Integrated Product Development Process

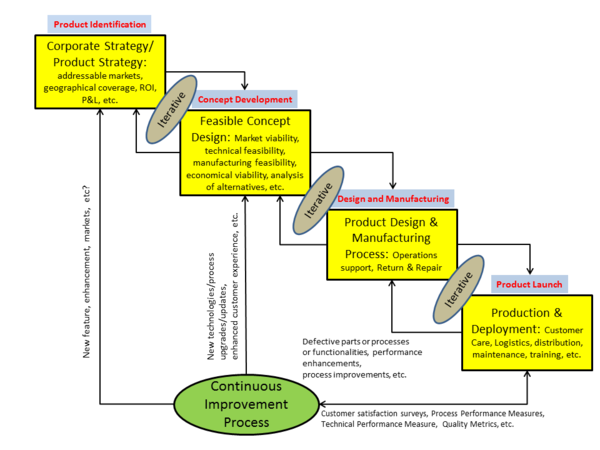

The integrated product development process (IPDP) starts with understanding market needs and developing a strategy that creates products that satisfy or exceed customer expectations, respond to evolving customer demands, adapt to changing business environments, and incorporate systems thinking to generate novel ideas and co-create value with extensive stakeholders’ participation. IPDP is a continuously evolving process that strives to realize products whose cost, performance, features, and time-to-market help increase company profitability and market share. Magrab, et al. (2010) discussed the IPDP in terms of four different stages; Figure 1 provides a snapshot of an IPDP and the main tasks carried out at each stage.

Stage I: Product Identification

During the product identification stage, the enterprise aims to identify an enterprise-wide strategy that flows down to individual product strategies resulting in a good business investment for the company. During this stage addressable markets for the product are identified in addition to geographical coverage of the product. The developments through this stage result in demonstration of strong customer need, determination of potential markets and geographic scope, the fitness of enterprise core capabilities to the product strategy, business profitability (return on investment, profit & loss), etc.

During this stage an integrated product team (IPT) first develops the IPDP for the project, usually by tailoring a corporate IPDP standard. The IPT assesses required technology innovation, feasibility of existing technologies, estimated time and cost of technology development, and the risks associated with markets, finances and technologies risk, etc. This stage also takes into account inputs from the continuous improvement (CI) process to develop new features and enhancements in existing products to address new market needs or customer demands.

Stage II: Concept Development

The main goal of the Concept Development stage is to generate feasible concepts for the potential product and develop MPTs that will satisfy the product’s performance goals of economic viability and customer satisfaction. These concept designs must ensure that the company’s core competencies can satisfy the requirements to produce the products while taking into account the market viability, manufacturability, and technical feasibility through an extensive analysis of alternative process.

During this stage SE supports the IPT in identifying different operational scenarios and modes of operation, functional requirements of the products, technology and performance risks, and the main components of the products and required interfaces among them, etc. This stage involves a highly interactive and iterative exchange of concepts among several IPTs and, depending on complexity of the products, a Systems Engineering Integration Team may be required to ensure analysis of all the possible solutions. During this stage inputs from the CI process helps analyze new technologies/processes including upgrades to existing technologies and create products that result in enhanced customer experiences.

Stage III: Design and Manufacturing

During the design and manufacturing stage the actual product is realized and manufactured. This stage starts with creating engineering drawings for the product, product configuration items specs, "design for X" (DFX), manufacturing design plans, production plans and schedules, test production run to ensure that the product meets customer requirements and quality criteria, and a plan for full production, logistics and distribution.

During this stage the product design & manufacturing engineering team works closely with operations managers to create MPTs to manage the technical effort for the product from an end-to-end perspective. Some of the SE activities during this stage include product integration, verification and validation plans; modeling, simulation, test & evaluation of the product system under critical scenarios; launch readiness plans including end-user test plans, operational readiness, etc. During this stage MPTs are developed and documented for proper handling of defective parts, processes, or functionalities. The CI process inputs include product and process performance enhancements and sustained life-cycle operations support.

Stage IV: Product Launch

During the product launch stage, the product is delivered to its potential markets. During production and deployment, MPTs are developed to ensure that the product meets its quality goals, satisfies customer requirements, and realizes the business plan goals. This requires provisions for customer care, logistics, maintenance, training etc., and a CI process to monitor product and product system technical performance and product quality. The CI process is realized through extensive data collection using customer satisfaction surveys and remotely or manually observing, recording, and analyzing process performance metrics, technical performance measure, quality metrics, etc.

Relationship between Product Systems Engineering and Technology Development

As technological advancement accelerates, product life cycles become shorter, especially for high technology products. As a result, enterprises risk having outdated or obsolete products that have lost pace with markets trends, technology trends, or customer expectations.

Product systems engineering should bring awareness of technology changes and trends to the analysis of new product ideas or innovations. This affects the time and cost inputs into the technical feasibility analysis of the product. The result should include a road map of required technology developments, which is then used to create the overall road map for the new product offering.

In these cases, new product ideas impose requirements on new technology developments.

On the other hand, when technology developments or breakthroughs drive product innovation or the generation of new markets, the technology developments may also generate requirements on product features and functionalities. Factors which dictate decisions about introducing products include the technology readiness levels (TRL), the integration readiness levels (IRL), the manufacturing readiness levels (MRL), the system readiness levels (SRL), and the operational readiness of the enterprise to launch the product system. See the "Readiness Levels" section in the Product Systems Engineering Special Activities article.

Understanding the entities (i.e., components or elements) that compose the product is not a trivial task for systems engineers. It is not unusual for a new product to require developments in several technologies, including new materials, electronic components, software, maintenance and repair procedures, processes, or organizational structures. All of these developments must be factored into the IPDP for the successful deployment and proper use of the product.

Product Type Examples

Examples of each product type are shown below (Martin 1997).

| Type | Examples |

|---|---|

| Hardware | Computer processor unit, radar transmitter, satellite payload, telephone, diesel engine, data storage device, network router, airplane landing gear |

| Software | Computer operating system, firmware, satellite control algorithm, robot control code, telephone switching software, database application |

| Personnel | Astronaut, computer operator, clerk, business executive, Laika (the cosmonaut dog), bus driver, cashier, maintenance technician |

| Facilities | Space rocket launch pad, warehouse building, shipping docks, airport runway, railroad tracks, conference room, traffic tunnel, bridge, local area network cables |

| Data | Personnel records, satellite telemetry data, command and control instructions, customer satisfaction scores |

| Materials | Graphite composite, paper, gold, concrete, stone, fiberglass, radar absorption material, cladded metals, integrated circuit substrate, magnetic memory core |

| Media | Data storage media (tape, disc, memory card), signal transport media (twisted pair wire, fiber optic cable, RF spectrum), communications media (television, radio, magazines), social media (blogs, Twitter, Facebook) |

| Techniques | Soldering, trouble trick response process, change notice handling, telephone answering protocol, project scheduling, data sorting algorithm |

Materials could be thought of as basic raw materials, like steel, or as complex materials, like cladded metals, graphite composites, or building aggregate material. Personnel are not normally thought of as a “product,” but that can change depending on the type of system in question. The National Aeronautics and Space Administration (NASA) space program “system” certainly produces astronauts. When personnel are considered product(s), it is not usually possible to simply find and hire personnel with the requisite knowledge, skills, and experience. These personnel “products” can often be developed using a product SE approach (Martin 1996). For example, you could specify requirements (i.e., required knowledge, skills, and experience) for each person that is part of the system. Interfaces can be specified for each person, and an assessment can be made as to the maturity of each person (i.e., each potential product). These are a few examples of how product SE can be applied to personnel products.

In enterprise systems engineering, we may need education and training systems to make up a part of our personnel system in order to produce people with the right competencies and capabilities.

References

Works Cited

Academy of Program/Project and Engineering Leadership (APPEL). 2009. NASA's Systems Engineering Competencies. Washington, D.C., USA: US National Aeronautics and Space Association. Available at: http://www.nasa.gov/offices/oce/appel/pm-development/pm_se_competency_framework.html.

Blanchard, B.S., and W.J. Fabrycky. 2011. Systems Engineering and Analysis, 5th ed. Prentice Hall International Series in Industrial and Systems Engineering. Englewood Cliffs, NJ, USA: Prentice Hall.

Boehm, B. 2010. Systems 2020 Strategic Initiative. Hoboken, NJ, USA: Systems Engineering Research Center (SERC), SERC-2010-TR-009.

Grady, J. 2010. Systems Synthesis - Product and Process Design. Boca Raton, FL, USA: CRC Press.

INCOSE. 2012. Systems Engineering Handbook: A Guide for System Life Cycle Processes and Activities, version 3.2.2. San Diego, CA, USA: International Council on Systems Engineering (INCOSE), INCOSE-TP-2003-002-03.2.2.

Magrab, E., S. Gupta, P. McCluskey, and P. Sandborn. 2010. Integrated Product and Process Design and Development - The Product Realization Process. Boca Raton, FL, USA: CRC Press.

Martin, J.N. 1997. Systems Engineering Guidebook: A process for developing systems and products, 1st ed. Boca Raton, FL, USA: CRC Press.

MITRE. 2010. Platform as a Service: A 2010 Marketplace Analysis, Cloud Computing Series. Bedford, MA, USA: Systems Engineering at MITRE.

Morse, L., and D. Babcock. 2007. Managing Engineering and Technology, 4th ed. Upper Saddle River, NJ, USA: Prentice Hall.

Phillips, F. 2001. Market Oriented Technology Management: Innovating for Profit in Entrepreneurial Times. New York, NY, USA: Springer.

Trudeau, P.N. 2010. Designing and Enhancing a Systems Engineering Training and Development Program. Bedford, MA, USA: The MITRE Corporation.

Wasson, C.S. 2006. System Analysis, Design, and Development. New York, NY, USA: John Wiley & Sons.

Primary References

Grady, J. 2010. Systems Synthesis - Product and Process Design. Boca Raton, FL, USA: CRC Press.

Magrab, E., S. Gupta, P. McCluskey, and P. Sandborn. 2010. Integrated Product and Process Design and Development - The Product Realization Process. Boca Raton, FL, USA: CRC Press.

Martin, J.N. 1997. Systems Engineering Guidebook: A process for developing systems and product, 1st ed. Boca Raton, FL, USA: CRC Press.

Additional References

Academy of Program/Project and Engineering Leadership (APPEL). 2009. NASA's Systems Engineering Competencies. Washington, D.C., USA: US National Aeronautics and Space Association. Available at: http://www.nasa.gov/offices/oce/appel/pm-development/pm_se_competency_framework.html.

Blanchard, B.S., and W.J. Fabrycky. 2011. Systems Engineering and Analysis, 5th ed. Prentice Hall International Series in Industrial and Systems Engineering. Englewood Cliffs, NJ, USA: Prentice Hall.

Boehm, B. 2010. Systems 2020 Strategic Initiative. Hoboken, NJ, USA: Systems Engineering Research Center (SERC), SERC-2010-TR-009.

INCOSE. 2012. Systems Engineering Handbook: A Guide for System Life Cycle Processes and Activities, version 3.2.2. San Diego, CA, USA: International Council on Systems Engineering (INCOSE), INCOSE-TP-2003-002-03.2.2.

MITRE. 2010. Platform as a Service: A 2010 Marketplace Analysis, Cloud Computing Series. Bedford, MA, USA: Systems Engineering at MITRE.

Morse, L., and D. Babcock. 2007. Managing Engineering and Technology, 4th ed. Upper Saddle River, NJ, USA: Prentice Hall.

Phillips, F. 2001. Market Oriented Technology Management: Innovating for Profit in Entrepreneurial Times. New York, NY, USA: Springer.

Trudeau, P.N. 2010. Designing and Enhancing a Systems Engineering Training and Development Program. Bedford, MA, USA: The MITRE Corporation.

Wasson, C.S. 2006. System Analysis, Design, and Development. New York, NY, USA: John Wiley & Sons.