Difference between revisions of "Standard Korean Light Transit System"

Wikiexpert (talk | contribs) |

m (Text replacement - "SEBoK v. 2.9, released 13 November 2023" to "SEBoK v. 2.9, released 20 November 2023") |

||

| (35 intermediate revisions by 10 users not shown) | |||

| Line 1: | Line 1: | ||

| − | This | + | ---- |

| − | + | '''''Lead Authors:''''' ''Heidi Davidz, Alice Squires, Chuck Calvano'', '''''Contributing Authors:''''' ''Richard Turner'' | |

| − | + | ---- | |

| + | This example was created as a SE example directly for the SEBoK. It deals with {{Term|Systems Engineering (glossary)|systems engineering}} (SE) concepts and guidelines applied to the development of the Standard Korean Light Transit System (SKLTS). In Korea, local authorities had historically been interested in light transit to help resolve their transportation problems. The SKLTS was a joint effort between local authorities and the central government. It was built to provide a standard platform on which any local authority could construct its own light transit system. The issues of [[Stakeholder Needs and Requirements|stakeholder requirements]], [[System Safety|safety]], and [[System Reliability, Availability, and Maintainability|reliability, availability, and maintainability]] were critical to the success of this system. | ||

| − | + | ==Description== | |

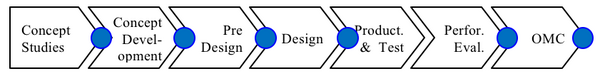

| + | The elements of the SKLTS were classified into four groups (as shown in Figure 1): trains, signal systems, electric and machinery (E&M) systems, and structures. Trains and vehicles were to be automatically operated, without need for human operators. Operation systems and their interfaces were based on digital signals and communications. For SKLTS, SE-based design activities focused on reliability, availability, maintainability, and safety (RAMS), and were integrated into project management (PM) activities during all phases. | ||

| + | [[File:ChoeKimFigure1.png|thumb|center|600px|'''Figure 1. Subsystems of the SKLTS (Ahn, 2005).''' (Notes: CCU: Central Control Unit; TTC: Total Traffic Control; ATP: Automatic Train Protection; ATO: Automatic Train Operation; PSD: Platform Screen Door) Reprinted with permission of ''Journal of the Korean Society for Railway''. All other rights are reserved by the copyright owner.]] | ||

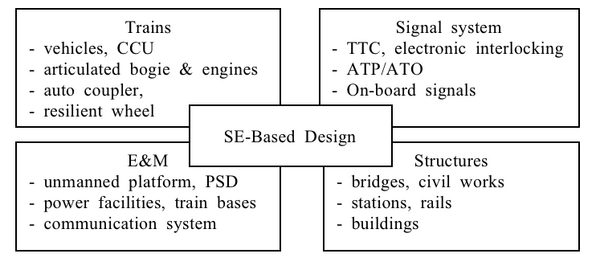

| − | + | The [[Life Cycle Models|project life cycle]] for the SKLTS is summarized in Figure 2. It consisted of 7 phases: concept studies, concept development, preliminary design, design, system production and testing, performance evaluation, and operation/maintenance/close-out (OMC) - please see (Choi 2007) and (Chung et al. 2010) for further details. These phases, with the exception of the production and test phases, are completed through an evaluation and decision point (EDP) ({{Term|Milestone (glossary)|milestone}}), depicted as a colored circle in Figure 2. These EDPs correspond to common life cycle artifacts such as requests for proposal (RFPs), proposals, preliminary design reviews (PDRs), and critical design reviews (CDRs). | |

| − | The | ||

| − | [[File: | + | [[File:ChoeKimFigure2.png|thumb|center|600px|'''Figure 2. 7 phases of the SKLTS development (Ahn 2005).''' Reprinted with permission of the ''Journal of the Korean Society for Railway''. All other rights are reserved by the copyright owner.]] |

| − | + | During the SKLTS development, SE activities were focused on RAMS as summarized in Table 1. | |

| + | {| | ||

| + | |+'''Table 1. The SE Framework of the SKLTS (Ahn 2005).''' Reprinted with permission of the ''Journal of the Korean Society for Railway''. All other rights are reserved by the copyright owner. | ||

| + | !Phases | ||

| + | !Safety | ||

| + | !Reliability | ||

| + | !Function | ||

| + | !Performance | ||

| + | |- | ||

| + | |Concept studies | ||

| + | | | ||

| + | *Requirements analysis | ||

| + | | | ||

| + | *Identifying RAM conditions | ||

| + | *RAM allocation | ||

| + | | | ||

| + | *System configuration | ||

| + | *Interface management | ||

| + | | | ||

| + | *Performance simulation | ||

| + | |- | ||

| + | |Concept development & pre-design | ||

| + | | | ||

| + | *Safety planning | ||

| + | *Defining safety procedures & levels | ||

| + | | | ||

| + | *RAM planning | ||

| + | *Initial availability analysis | ||

| + | | | ||

| + | *Defining scenarios and alarm procedure | ||

| + | *Pre-designing command rooms | ||

| + | | | ||

| + | *Interface analysis | ||

| + | |- | ||

| + | |Design | ||

| + | | | ||

| + | *Hazard log | ||

| + | *Safety case analysis | ||

| + | *Risk analysis | ||

| + | | | ||

| + | *Reporting RAM analysis | ||

| + | *RAM analysis of auxiliary systems | ||

| + | | | ||

| + | *Defining alarm systems | ||

| + | *Train analysis | ||

| + | *Functionality analysis of stations | ||

| + | | | ||

| + | *Interface analysis | ||

| + | |- | ||

| + | |Performance evaluation | ||

| + | | | ||

| + | *Safety test planning & testing | ||

| + | | | ||

| + | *Verification and Validation (V&V) RAM | ||

| + | *Maintainability test | ||

| + | | | ||

| + | *System test planning and testing | ||

| + | | | ||

| + | *Performance test planning & testing | ||

| + | |- | ||

| + | |Initial Operation | ||

| + | | | ||

| + | *System acceptance | ||

| + | *Driver certification | ||

| + | | | ||

| + | *RAM monitoring | ||

| + | *FRACAS<nowiki>*</nowiki> | ||

| + | | | ||

| + | *Analyzing systems | ||

| + | *Identifying improvement points | ||

| + | | | ||

| + | *Performance monitoring | ||

| + | |} | ||

| − | + | <nowiki>*</nowiki>FRACAS: Failure Reporting & Corrective Action System | |

| + | In the "concept studies" and "concept development" phases, requirements included the RAMS objectives. Planning activities in this phase included the scheduling of various tests and evaluations to be conducted after system design. The basic layout of rails and command rooms was also proposed. Finally, it was during this phase that interface management procedures and relationships between requirements and systems were defined. For RAMS engineering, it was also important to establish associated plans and criteria (e.g., RAM plans, safety plans, service availability, etc.). | ||

| − | During the | + | During the pre-design phase, the basic architecture of the system was determined for safety planning, RAMS planning, and operational scenarios. Interfaces among subsystems, management procedures for contractors and legal regulations were defined. were defined as well as management procedures for contractors and legal regulations. The functional analysis dealt with timeline, accuracy of stop points, and trip times. Pre-design activities also included the specifications of major system elements such as signal systems, trains, and interfaces. For RAMS engineering, safety scenarios were defined, and the hazard and risk analyses were performed. |

| − | |||

| − | + | During the design and performance evaluation phases, hazard log and RAMS analyses were performed to ensure that each subsystem met safety requirements. The specifications of alarm systems and stations were also defined. In addition, V&V and test procedures were determined for performance evaluation. During the design phase, a design/construction interface manual (D/CIM) was developed and applied to ensure integrated and consistent [[System Definition|design]]. (Bombardier, 2005.) | |

| − | |||

| − | + | Because SKLTS was designed as an automatically-driven system, RAMS issues were critical to its success. The safety and reliability of the SKLTS were evaluated on a test railway that was constructed to standard specifications. Data was gathered from existing Korean light rail systems, as well as the light rail systems from other countries, to support V&V activities. | |

| − | + | Various methods were applied for achieving the RAMS objectives, including RAMS requirements analysis, safety and RAMS planning, utilization of systems scenarios, and construction risk analysis. | |

| − | + | Initial operation of SKLTS was allowed only after the system was formally accepted and operators were properly certified. During test operation, RAMS performance was continuously monitored and system scenarios were used successfully to evaluate the dynamic behavior of the system. A failure reporting and corrective action system (FRACAS) was used to gather accident and failure data. Continuous improvement when the system is in normal operation was identified as a requirement; the results from the FRACAS will be used to support improvement of the system, maintenance, and improvement of procedures. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | Initial operation of | ||

==Summary== | ==Summary== | ||

| − | Korean local authorities have successfully introduced the | + | Korean local authorities have successfully introduced the SKLTS to their precincts with some modifications. Successful examples include the Inchun Airport Line and the Seoul 9th Subway Line. One lesson learned that was identified was that requirement analysis, especially in the first few phases, should have been more complete. |

==References== | ==References== | ||

| Line 44: | Line 111: | ||

Bombardier. 2005. ''Design/Construction Interface Manual''. Montréal, Québec, Canada: Bombardier. | Bombardier. 2005. ''Design/Construction Interface Manual''. Montréal, Québec, Canada: Bombardier. | ||

| − | Choi, Y.C. 2007. "Systems | + | Choi, Y.C. 2007. "Systems eEngineering aApplication mModel for the nNational R&D pProject: Focusing on the rRailway sSystems." Ph.D. dissertation, Ajou University, Suwon, South Korea, 2007. |

| − | Chung, S. Y., S.G. Lee, D.W. Lee, and S.T. Jeon. 2010. “A | + | Chung, S. Y., S.G. Lee, D.W. Lee, and S.T. Jeon. 2010. “A sStudy on tThe aApplication mModel of sSystems eEngineering to Aadvance the bBusiness of the Light Rail Transit (LRT).” Proceedings on the Autumn Conference of the Korean Society for Railway, p. 24-30. |

===Primary References=== | ===Primary References=== | ||

| − | + | None. | |

===Additional References=== | ===Additional References=== | ||

| − | Han, S.Y. and A.H. Lee. 2005. ''System Engineering for The Technology Development Program of Light Transit Systems: Internal Research Report.'' | + | Han, S.Y. and A.H. Lee. 2005. ''System Engineering for The Technology Development Program of Light Transit Systems: Internal Research Report.'' Gyeonggi-do, South Korea: Korea Railroad Research Institute. |

| − | Korean Agency for Technology and Standards. 2009. ''KSX ISO/IEC 15288: Life Cycle Processes of IT Systems Based on Systems and Software Engineering, Research Report.'' Gyeonggi-do, Korea: Korean Agency for Technology and Standards. | + | Korean Agency for Technology and Standards. 2009. ''KSX ISO/IEC 15288: Life Cycle Processes of IT Systems Based on Systems and Software Engineering, Research Report.'' Gyeonggi-do, South Korea: Korean Agency for Technology and Standards. |

| − | Lee, W.D. 2002. “A | + | Lee, W.D. 2002. “A study on the top-level functional analysis for the automated guideway transit by system engineering tools.” Proceedings of the Autumn Conference of the Korean Society for Railway, p. 202-207. |

---- | ---- | ||

| − | <center>[[ | + | <center>[[UK West Coast Route Modernisation Project|< Previous Article]] | [[Matrix of Implementation Examples|Parent Article]] | [[Northwest Hydro System|Next Article >]] </center> |

| − | |||

| − | |||

| − | |||

| + | <center>'''SEBoK v. 2.9, released 20 November 2023'''</center> | ||

| − | [[Category: Part 7]][[Category: | + | [[Category: Part 7]][[Category:Example]] |

| − | |||

Latest revision as of 23:31, 18 November 2023

Lead Authors: Heidi Davidz, Alice Squires, Chuck Calvano, Contributing Authors: Richard Turner

This example was created as a SE example directly for the SEBoK. It deals with systems engineering (SE) concepts and guidelines applied to the development of the Standard Korean Light Transit System (SKLTS). In Korea, local authorities had historically been interested in light transit to help resolve their transportation problems. The SKLTS was a joint effort between local authorities and the central government. It was built to provide a standard platform on which any local authority could construct its own light transit system. The issues of stakeholder requirements, safety, and reliability, availability, and maintainability were critical to the success of this system.

Description

The elements of the SKLTS were classified into four groups (as shown in Figure 1): trains, signal systems, electric and machinery (E&M) systems, and structures. Trains and vehicles were to be automatically operated, without need for human operators. Operation systems and their interfaces were based on digital signals and communications. For SKLTS, SE-based design activities focused on reliability, availability, maintainability, and safety (RAMS), and were integrated into project management (PM) activities during all phases.

The project life cycle for the SKLTS is summarized in Figure 2. It consisted of 7 phases: concept studies, concept development, preliminary design, design, system production and testing, performance evaluation, and operation/maintenance/close-out (OMC) - please see (Choi 2007) and (Chung et al. 2010) for further details. These phases, with the exception of the production and test phases, are completed through an evaluation and decision point (EDP) (milestone), depicted as a colored circle in Figure 2. These EDPs correspond to common life cycle artifacts such as requests for proposal (RFPs), proposals, preliminary design reviews (PDRs), and critical design reviews (CDRs).

During the SKLTS development, SE activities were focused on RAMS as summarized in Table 1.

| Phases | Safety | Reliability | Function | Performance |

|---|---|---|---|---|

| Concept studies |

|

|

|

|

| Concept development & pre-design |

|

|

|

|

| Design |

|

|

|

|

| Performance evaluation |

|

|

|

|

| Initial Operation |

|

|

|

|

*FRACAS: Failure Reporting & Corrective Action System

In the "concept studies" and "concept development" phases, requirements included the RAMS objectives. Planning activities in this phase included the scheduling of various tests and evaluations to be conducted after system design. The basic layout of rails and command rooms was also proposed. Finally, it was during this phase that interface management procedures and relationships between requirements and systems were defined. For RAMS engineering, it was also important to establish associated plans and criteria (e.g., RAM plans, safety plans, service availability, etc.).

During the pre-design phase, the basic architecture of the system was determined for safety planning, RAMS planning, and operational scenarios. Interfaces among subsystems, management procedures for contractors and legal regulations were defined. were defined as well as management procedures for contractors and legal regulations. The functional analysis dealt with timeline, accuracy of stop points, and trip times. Pre-design activities also included the specifications of major system elements such as signal systems, trains, and interfaces. For RAMS engineering, safety scenarios were defined, and the hazard and risk analyses were performed.

During the design and performance evaluation phases, hazard log and RAMS analyses were performed to ensure that each subsystem met safety requirements. The specifications of alarm systems and stations were also defined. In addition, V&V and test procedures were determined for performance evaluation. During the design phase, a design/construction interface manual (D/CIM) was developed and applied to ensure integrated and consistent design. (Bombardier, 2005.)

Because SKLTS was designed as an automatically-driven system, RAMS issues were critical to its success. The safety and reliability of the SKLTS were evaluated on a test railway that was constructed to standard specifications. Data was gathered from existing Korean light rail systems, as well as the light rail systems from other countries, to support V&V activities.

Various methods were applied for achieving the RAMS objectives, including RAMS requirements analysis, safety and RAMS planning, utilization of systems scenarios, and construction risk analysis.

Initial operation of SKLTS was allowed only after the system was formally accepted and operators were properly certified. During test operation, RAMS performance was continuously monitored and system scenarios were used successfully to evaluate the dynamic behavior of the system. A failure reporting and corrective action system (FRACAS) was used to gather accident and failure data. Continuous improvement when the system is in normal operation was identified as a requirement; the results from the FRACAS will be used to support improvement of the system, maintenance, and improvement of procedures.

Summary

Korean local authorities have successfully introduced the SKLTS to their precincts with some modifications. Successful examples include the Inchun Airport Line and the Seoul 9th Subway Line. One lesson learned that was identified was that requirement analysis, especially in the first few phases, should have been more complete.

References

Works Cited

Ahn, S.H. 2005. “Systems Engineering Applied to the Construction of Unmanned Light Rail Transit Systems.” Journal of the Korean Society for Railway. 8(2): 41-49.

Bombardier. 2005. Design/Construction Interface Manual. Montréal, Québec, Canada: Bombardier.

Choi, Y.C. 2007. "Systems eEngineering aApplication mModel for the nNational R&D pProject: Focusing on the rRailway sSystems." Ph.D. dissertation, Ajou University, Suwon, South Korea, 2007.

Chung, S. Y., S.G. Lee, D.W. Lee, and S.T. Jeon. 2010. “A sStudy on tThe aApplication mModel of sSystems eEngineering to Aadvance the bBusiness of the Light Rail Transit (LRT).” Proceedings on the Autumn Conference of the Korean Society for Railway, p. 24-30.

Primary References

None.

Additional References

Han, S.Y. and A.H. Lee. 2005. System Engineering for The Technology Development Program of Light Transit Systems: Internal Research Report. Gyeonggi-do, South Korea: Korea Railroad Research Institute.

Korean Agency for Technology and Standards. 2009. KSX ISO/IEC 15288: Life Cycle Processes of IT Systems Based on Systems and Software Engineering, Research Report. Gyeonggi-do, South Korea: Korean Agency for Technology and Standards.

Lee, W.D. 2002. “A study on the top-level functional analysis for the automated guideway transit by system engineering tools.” Proceedings of the Autumn Conference of the Korean Society for Railway, p. 202-207.