Difference between revisions of "Systems Engineering and Environmental Engineering"

m (Text replacement - "{{DISQUS}}" to "SEBoK v. 1.9.1 released 5 October 2018") |

|||

| Line 175: | Line 175: | ||

<center>[[Affordability|< Previous Article]] | [[Systems Engineering and Specialty Engineering|Parent Article]] | [[Systems Engineering Implementation Examples|Next Article (Part 7) >]]</center> | <center>[[Affordability|< Previous Article]] | [[Systems Engineering and Specialty Engineering|Parent Article]] | [[Systems Engineering Implementation Examples|Next Article (Part 7) >]]</center> | ||

| − | + | <center>'''SEBoK v. 1.9.1, released 16 October 2018'''</center> | |

[[Category:Part 6]][[Category:Topic]] | [[Category:Part 6]][[Category:Topic]] | ||

[[Category:Systems Engineering and Specialty Engineering]] | [[Category:Systems Engineering and Specialty Engineering]] | ||

| − | |||

Revision as of 04:51, 16 October 2018

Environmental engineering addresses four issues that arise in system design and operation. They include: (1) design for a given operating environment, (2) environmental impact, (3) green design, and (4) compliance with environment regulations.

Please note that not all of the generic below sections have mature content at this time. Anyone wishing to offer content suggestions should contact the SEBoK Editors in the usual ways.

Overview

A system is designed for a particular operating environment. Product systems, in particular, routinely consider conditions of temperature and humidity. Depending on the product, other environmental conditions may need to be considered, including UV exposure, radiation, magnetic forces, vibration, and others. The allowable range of these conditions must be specified in the requirements for the system.

Requirements

The general principles for writing requirements also apply to specifying the operating environment for a system and its elements. Requirements are often written to require compliance with a set of standards.

System Description

Information to be supplied at a later date.

Discipline Management

Many countries require assessment of environmental impact of large projects before regulatory approval is given. The assessment is documented in an environmental impact statement (EIS). In the United States, a complex project can require an EIS that greatly adds to the cost, schedule, and risk of the project.

Scope

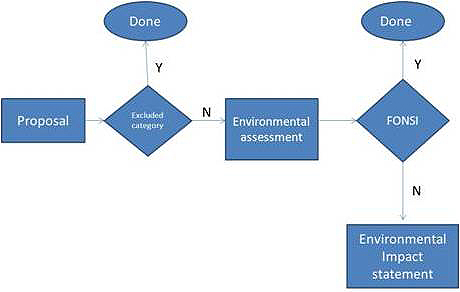

In the U.S., the process in Figure 1 is followed. A proposal is prepared prior to a project being funded. The regulator examines the proposal. If it falls into an excluded category, no further action is taken. If not, an environmental assessment is made. If that assessment determines a finding of no significant impact (FONSI), no further action is taken. In all other cases, an environmental impact statement is required.

Preparation of an EIS is a resource significant task. Bregman (2000) and Kreske (1996) provide accessible overviews of the process. Lee and Lin (2000) provide a handbook of environmental engineering calculations to aid in the technical submission. Numerous firms offer consulting services.

Legal References

Basic references in the U.S. include the National Environmental Policy Act of 1969 and its implementing regulations (NEPA 1969) and the European commission directive (EC 1985). State and local regulations can be extensive; Burby and Paterson (1993) discuss improving compliance.

Cost and Schedule Implications

Depending on the scale of the project, the preparation of an EIS can take years and cost millions. For example, the EIS for the Honolulu light rail project took four years and cost $156M (Hill 2011). While a project may proceed even if the EIS finds a negative impact, opponents to a project may use the EIS process to delay a project. A common tactic is to claim the EIS was not complete in that it omitted some environmental impacts. Eccleston (2000) provides a guide to planning for EIS.

Energy Efficiency

There is a large amount of literature that has been published about design for energy efficiency. Lovins (2010) offer ten design principles. He also provides case studies (Lovins et al. 2011). Intel (2011) provides guidance for improving the energy efficiency of its computer chips. A great deal of information is also available in regard to the efficient design of structures; DOE (2011) provides a good overview.

Increased energy efficiency can significantly reduce total life cycle cost for a system. For example, the Toyota Prius was found to have the lowest life cycle cost for 60,000 miles, three years despite having a higher initial purchase price (Brown 2011).

Carbon Footprint

Increased attention is being paid to the emission of carbon dioxide. BSI British Standards offers a specification for assessing life cycle greenhouse emissions for goods and services (BSI 2011).

Sustainability

Graedel and Allenby (2009), Maydl (2004), Stasinopoulos (2009), Meryman (2004), and Lockton and Harrison (2008) discuss design for sustainability. Sustainability is often discussed in the context of the UN report on Our Common Future (WCED 1987) and the Rio Declaration (UN 1992).

Discipline Relationships

An enterprise must attend to compliance with the various environmental regulations. Dechant et al. (1994) provide the example of a company in which 17% of every sales dollar goes toward compliance activities. They discuss gaining a competitive advantage through better compliance. Gupta (1995) studies how compliance can improve the operations function. Berry (1998) and Nash (2001) discuss methods for environmental management by the enterprise.

Interactions

Information to be supplied at a later date.

Dependencies

ISO14001 sets the standards for organization to comply with environmental regulations. Kwon and Seo (2002) discuss this in a Korean context, and Whitelaw (2004) presents a handbook on implementing ISO14001.

Discipline Standards

Depending on the product being developed, standards may exist for operating conditions. For example, ISO 9241-6 specifies the office environment for a video display terminal. Military equipment may be required to meet MILSTD 810G standard (DoD 2014) in the US, or DEF STAN 00-35 in the UK (MoD 2006).

The U.S. Federal Aviation Administration publishes a list of EIS best practices (FAA 2002).

The U.S. Environmental Protection Agency (EPA) defines green engineering as: the design, commercialization, and use of processes and products, which are feasible and economical, while minimizing (1) generation of pollution at the source and (2) risk to human health and the environment (EPA 2011). Green engineering embraces the concept that decisions to protect human health and the environment can have the greatest impact and cost effectiveness when applied early to the design and development phase of a process or product.

The EPA (2011) offers the following principles of green engineering:

- Engineer processes and products holistically, use systems analysis, and integrate environmental impact assessment tools.

- Conserve and improve natural ecosystems while protecting human health and well-being.

- Use life-cycle thinking in all engineering activities.

- Ensure that all material and energy inputs and outputs are as inherently safe and benign as possible.

- Minimize depletion of natural resources.

- Strive to prevent waste.

- Develop and apply engineering solutions, while being cognizant of local geography, aspirations, and cultures.

- Create engineering solutions beyond current or dominant technologies; additionally, improve, innovate, and invent (technologies) to achieve sustainability.

- Actively engage communities and stakeholders in development of engineering solutions.

Personnel Considerations

Information to be supplied at a later date.

Metrics

Information to be supplied at a later date.

Models

Information to be supplied at a later date.

Tools

Information to be supplied at a later date.

Practical Considerations

Pitfalls

Information to be provided at a later date.

Proven Practices

Information to be provided at a later date.

Other Considerations

Information to be provided at a later date.

References

Works Cited

Berry, MA. 1998. "Proactive corporate environmental management: a new industrial revolution." The Academy of Management Executive, 12 (2): 38-50.

Bregman, J.I. 2000. Environmental Impact Statements, 2nd ed. Boca Raton, FL, USA: CRC Press.

Brown, C. 2011 "The Green Fleet Price Tag." Business Fleet. Available: http://www.businessfleet.com/Article/Story/2011/07/The-Green-Fleet-Price-Tag.aspx.

BSI. 2011. "Specification for the assessment of the life cycle greenhouse gas emissions of goods and service, PAS 2050:2011." London, UK: British Standards Institution (BSI). Available: http://shop.bsigroup.com/en/forms/PASs/PAS-2050.

Burby, R.J., and R.G. Paterson. 1993. "Improving compliance with state environmental regulations." Journal of Policy Analysis and Management, 12(4): 753–772.

Dechant, K., B. Altman, R.M. Downing, and T. Keeney. 1994. "Environmental Leadership: From Compliance to Competitive Advantage." Academy of Management Executive, 8(3): 7.

DoD. 2014. Department of Defense Test Method Standard: Environmental Engineering Considerations and Laboratory Tests, MIL-STD-810G Change Notice 1. Washington, DC, USA: US Army Test and Evaluation Command, US Department of Defense (DoD). Accessed November 4, 2014. Available: http://www.atec.army.mil/publications/Mil-Std-810G/MIL-STD-810G%20CN1.pdf.

Eccleston, C. 2000. Environmental Impact Statements: A Comprehensive Guide to Project and Strategic Planning. New York, NY, USA: Wiley.

EPA. 2011. "Green Engineering. Environmental Protection Agency (EPA)." Available: http://www.epa.gov/oppt/greenengineering/.

EC. 1985. "Council Directive of 27 June 1985 on the assessment of the effects of certain public and private projects on the environment (85/337/EEC)." European Commission (EC). Available: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:1985L0337:20090625:EN:PDF.

FAA. 2002. "Best Practices for Environmental Impact Statement (EIS) Management." Federal Aviation Administration (FAA). Available: http://www.faa.gov/airports/environmental/eis_best_practices/?sect=intro.

Graedel, T.E., and B.R. Allenby. 2009. Industrial Ecology and Sustainable Engineering. Upper Saddle River, NJ, USA: Prentice Hall.

Gupta, M.C. 1995. "Environmental management and its impact on the operations function." International Journal of Operations and Production Management, 15 (8): 34-51.

Hill, T. 2011. "Honolulu Rail's Next Stop?" Honolulu Magazine. July 2011.

Intel. 2011. "Energy Efficiency." Intel Corporation. Accessed: August 29, 2012. Available: http://www.intel.com/intel/other/ehs/product_ecology/energy.htm.

Kreske, D.L. 1996. Environmental impact statements: a practical guide for agencies, citizens, and consultants. New York, NY: Wiley.

Kwon, D.M., and M.S. Seo. 2002. "A study of compliance with environmental regulations of ISO 14001 certified companies in Korea." Journal of Environmental Management. 65 (4): 347-353.

Lee, C.C., and S.D. Lin. 2000. Handbook of Environmental Engineering Calculations. New York, NY, USA: McGraw Hill Professional.

Lockton, D., and D. Harrison. 2008. "Making the user more efficient: Design for sustainable behaviour." International Journal of Sustainable Engineering. 1 (1): 3-8.

Lovins, A. 2010. "Factor Ten Engineering Design Principles," version 1.0. Available: http://www.rmi.org/Knowledge-Center/Library/2010-10_10xEPrinciples.

Lovins, A., et al. 2011. "Case Studies." Available: http://move.rmi.org/markets-in-motion/case-studies/.

Maydl, Peter. 2004. "Sustainable Engineering: State-of-the-Art and Prospects." Structural Engineering International. 14 (3): 176-180.

Meryman, H. 2004. "Sustainable Engineering Using Specifications to Make it Happen." Structural Engineering International. 14 (3).

MoD. 2006. Standard 00-35, Environmental Handbook for Defence Materiel (Part 3) Environmental Test Methods. London, England, UK: UK Ministry of Defence (MoD). Available: http://www.everyspec.com/DEF-STAN/download.php?spec=DEFSTAN00-35_I4.029214.pdf.

Nash, J. 2001. Regulating from the inside: can environmental management systems achieve policy goals? Washington, DC, USA: Resources for the Future Press.

NEPA. 1969. 42 USC 4321-4347. National Environmental Policy Act (NEPA). Accessed January 15, 2012. Available: http://ceq.hss.doe.gov/nepa/regs/nepa/nepaeqia.htm.

Stasinopoulos, P. 2009. Whole system design: an integrated approach to sustainable engineering. London, UK: Routledge.

UN. 1992. "Rio Declaration on Environment and Development." United Nations (UN). Available: http://www.unep.org/Documents.Multilingual/Default.asp?documentid=78&articleid=1163.

Whitelaw, K. 2004. ISO 14001: Environmental Systems Handbook, 2nd ed. Oxford, UK: Elsevier.

WCED. 1987. "Our Common Future. World Commission on Economic Development (WCED)." Available: http://www.un-documents.net/wced-ocf.htm.

Primary References

Bregman, J.I. 2000. Environmental Impact Statements, 2nd ed. Boca Raton, FL, USA: CRC Press.

Graedel, T.E., and B.R. Allenby. 2009. Industrial Ecology and Sustainable Engineering. Upper Saddle River, NJ, USA: Prentice Hall.

Lee, C.C., and S.D. Lin. 2000. Handbook of Environmental Engineering Calculations. New York, NY, USA: McGraw Hill Professional.

Whitelaw, K. 2004. ISO 14001: Environmental Systems Handbook, 2nd ed. Oxford, UK: Elsevier.

Additional References

None.