Difference between revisions of "Systems Engineering and Industrial Engineering"

m (Text replacement - "SEBoK v. 2.9, released 13 November 2023" to "SEBoK v. 2.9, released 20 November 2023") |

|||

| (51 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

---- | ---- | ||

| − | '''''Lead Author:''''' '' | + | '''''Lead Author:''''' ''Gregory S. Parnell'', '''''Contributing Authors:''''' ''C. Robert Kenley, Eric Specking, Ed Pohl'' |

| − | ---- | + | ----Systems Engineering (SE) overlaps with many fields, such as Industrial Engineering (IE), Engineering Management, Operations Research, Project Management, and Design Engineering. In fact, the main Industrial Engineering body of knowledge, called the Industrial and Systems Engineering Body of Knowledge (ISEBoK) (IISE 2021), includes the word "systems" in its title and includes a section on systems design and engineering, which references the SEBoK. This article describes the similarities and differences between SE and IE based upon their respective standards, handbooks, and bodies of knowledge. Based on this assessment, this article describes potential roles that systems engineers and industrial engineers perform during a system’s life cycle. |

| − | |||

| − | + | = Introduction = | |

| + | When systems engineers and industrial engineers are in the same organization, they have different roles and responsibilities. While job titles vary by organization, many organizations have individuals that perform both SE and IE activities. This article tries to help systems engineers and industrial engineers better understand the different perspectives of the fields and the knowledge needed to meet the needs of their organizations and customers. The article compares the use of international standards and the contents of the bodies of knowledge for SE and IE. | ||

| − | + | = Systems Engineering = | |

| + | The International Council on Systems Engineering (INCOSE) is a “not-for-profit membership organization founded to develop and disseminate the interdisciplinary principles and practices that enable the realization of successful systems.” INCOSE defines systems engineering as<blockquote>''a transdisciplinary and integrative approach to enable the successful realization, use, and retirement of engineered systems, using systems principles and concepts, and scientific, technological, and management methods. (INCOSE 2021)''</blockquote>Here, the terms “engineering” and “engineered” are used in their widest sense: “the action of working artfully to bring something about.” “Engineered systems” may be composed of any or all of people, products, services, information, processes, and natural elements. | ||

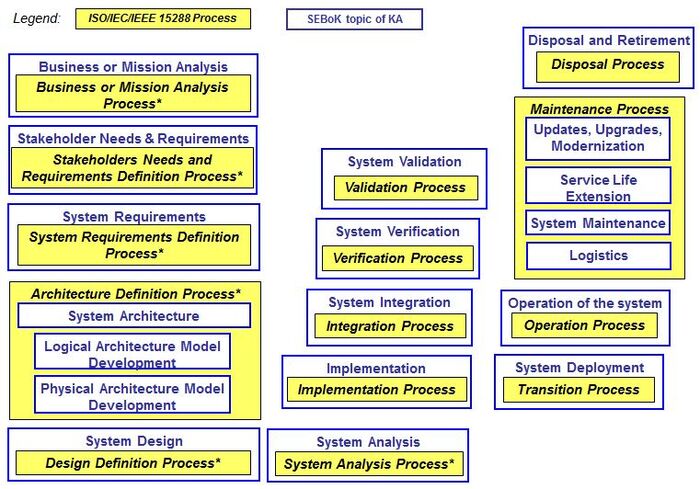

| − | + | INCOSE aligns its SE Handbook with ISO/IEC/IEEE 15288, System Life Cycle Processes, which focuses on processes. SEBoK Part 3 [[Systems Engineering and Management]], which addresses the major SE technical and management processes, is also organized around 15288 process areas. In this view, SE is process oriented. Each edition of the SE Handbook aligns to an ISO/IEC/IEEE 15288 edition. Figure 1 shows the 15288 processes and how they align with the SE Handbook and SEBoK topic areas. Later in this article, these SEBoK topics and knowledge areas are compared with the knowledge areas of IE. The knowledge areas in Figure 1 align with the system life cycle if started at the top of the first column and traversed to the bottom, continued at the bottom of the second column and traversed to the top, and then continued at the bottom of the third column and traversed to the top. | |

| − | + | [[File:Mapping_of_tech_topics_SEBoK_with_ISO_IEC_15288techPro_060612.jpg|thumb|700px|center|<center>'''Figure 1. Technical Topics of SEBoK Knowledge Areas Mapped to ISO/IEC/IEEE 15288 Technical Processes.''' (SEBoK 2022)</center>]] | |

| − | + | = Industrial Engineering = | |

| − | + | The Institute of Industrial and Systems Engineers (IISE) states that it is “the only international, non-profit, professional society dedicated to advancing the technical and managerial excellence of industrial engineers.” (IISE 2021). IISE started in 1948 as the American Institute of Industrial Engineers. In 1981, the organization was renamed the Institute of Industrial Engineers to reflect its growing international membership. In 2016, the membership voted to change the name to the Institute of Industrial and Systems Engineers. This addition reflects a vote by its membership and aligns with the “changing scope of the profession that, while keeping its industrial base, has seen more industrial and systems engineers working with large scale integrated systems in a variety of sectors”. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | Industrial engineers | + | At the turn of this century, industrial engineering was well reflected in two prominent publications: ''Handbook of Industrial Engineering'' (Salvendy 2001) and the fifth edition of ''Maynard's Industrial Engineering Handbook'' (Zandin 2001). Salvendy (2001) stated that industrial engineers are trained to design and analyze the components of which man-machine systems are composed. They bring together individual elements that are designed via other engineering disciplines and properly synergize these subsystems together with the people components for a completely integrated man-machine system. Industrial engineers are focused on the improvement of any system that is being designed or evaluated. They make individual human tasks more productive and efficient by optimizing flow, eliminating unnecessary motions, utilizing alternate materials to improve manufacturing, improving the flow of product through processes, and optimizing the configuration of workspaces. Fundamentally, the industrial engineer is charged with reducing costs and increasing profitability through ensuring the efficient use of human, material, physical, and/or financial resources. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The view of IE has evolved over the last two decades. IISE developed the IISE Body of Knowledge in 2021 (IISE 2021). The sixth edition of ''Maynard's Industrial Engineering Handbook'' (Zandin 2022) is expected to be published in 2022. The IISEBoK has 14 knowledge areas, as shown in Figure 2. The first 13 knowledge areas identify the Industrial Engineering knowledge. The fourteenth is Systems Design and Engineering, which references the SEBoK. The IISEBoK provides a short description of each knowledge area, a detailed outline of knowledge area topics, and a list of references. The IISEBoK does not use standards as its foundation. In fact, the Standard Practice for Systems Safety (MIL-STD-0-882D) is the only standard cited in the reference section. IISE does not currently have a handbook developed by or for the Institute, although Zandin (2022) is expected to align with the IISEBoK. | |

| − | + | [[File:IISE_BoK.jpeg|thumb|600px|center|''Figure 2. Industrial and Systems Engineering Knowledge Areas'' (IISE 2022, Used with Permission) [https://www.iise.org/BodyofKnowledge]]] | |

| − | The | + | The 14 topic areas included in the IISEBoK could be tied to many international standards even though the IISEBoK does not use standards as its foundation or provide references to standards in most of its topic areas. |

| − | == | + | = Venn Diagram Comparison = |

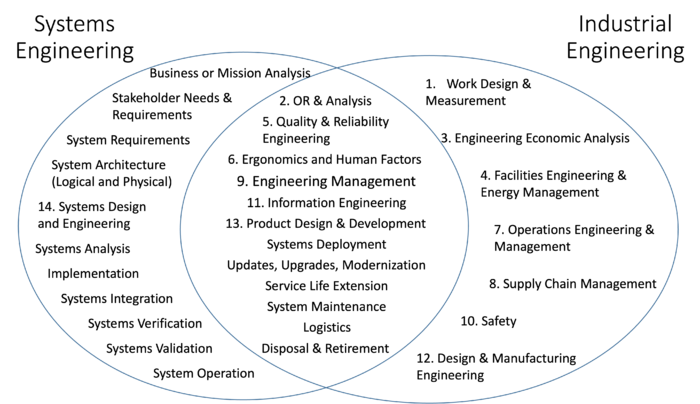

| + | This section compares the two bodies of knowledge. Figure 3 is a Venn Diagram that identifies knowledge areas that are usually performed by systems engineers, ones usually performed by industrial engineers, and ones that are used by both disciplines. | ||

| − | + | [[File:SE&IE_Venn.png|thumb|center|700px|''Figure 3. Venn Diagram'' (SEBoK Original]] | |

| − | + | There are 11 primarily SE knowledge areas, 7 primarily IE knowledge areas, and 12 overlapping knowledge areas. Table 1 provides some illustrative examples of the differences in SE and IE focus in the overlapping knowledge areas. | |

| − | Operations | + | {| class="wikitable" |

| + | |+Table 1. Illustrative Examples of Differences in SE and IE Focus | ||

| + | |- | ||

| + | |Knowledge Area | ||

| + | |Systems Engineering Focus | ||

| + | |Industrial Engineering Focus | ||

| + | |- | ||

| + | |2. Operations Research (OR) and Analysis | ||

| + | |OR and analysis is used in systems analysis to assess system performance and to evaluate system designs (Levis and Wagenhals 2000; Wagenhals, Shin, Kim, and Levis 2000; Wagenhals, Haider, and Levis 2003; Raz, Kenley, and DeLaurentis 2018) | ||

| + | |OR and analysis is used to optimize operations, maintenance, and logistics. OR is also used to evaluate and optimize manufacturing systems. | ||

| + | |- | ||

| + | |5. Quality & Reliability Engineering | ||

| + | |Quality and reliability requirements are treated as system-wide performance requirements (Buede and Miller 2016: 157-159; Wymore 1993: 401) that are assessed at the systems level. One example is availability, A<sub>0</sub>, which measures the degree to which a system is either operating or can operate at any time when used in its typical operational and support environment. (DA PAM 70-3 2008: 87) | ||

| + | |Quality and reliability are used to evaluate and improve the manufacturing process of goods and services. Reliability is also used to evaluate and improve system operations. | ||

| + | |- | ||

| + | |6. Ergonomics and Human Factors | ||

| + | |Ergonomics and human factors are considerations in assessing the potential usability of a system for end-users in an operational environment. According to Buede and Miller (2016: 180), “Performance elements of usability are ease of learning (learnability), ease of use (efficiency), ease of remembering (memorability), error rate, and subjectively pleasing (satisfaction).” | ||

| + | |Ergonomics and human factors are used to assess and improve manufacturing and operational processes. They are also used to assess and improve the actual usability of products and services. | ||

| + | |- | ||

| + | |9. Engineering Management | ||

| + | |Engineering managers and SEs work with program managers to develop and improve new products and services. | ||

| + | |Engineering managers and IEs support operations managers responsible for manufacturing processes and the operation of systems providing products and services. | ||

| + | |- | ||

| + | |11. Information Engineering | ||

| + | |Information Engineering is critical to the development of new products and services that are increasingly software intensive. Information engineering is relevant for model-based systems engineering software tools and databases, requirements management software tools and databases, and overall configuration management of the systems design and requirements baseline. | ||

| + | |The Information Engineering knowledge area focuses on using data in information systems to facilitate decision-making and business communication. | ||

| + | |- | ||

| + | |13. Product Design and Development | ||

| + | |SE focuses on the design of systems that provide products and services and the system life cycle. SE includes the technical processes for system design and verification and the technical management processes for project planning, assessment, and control; risk management; and decision management in the ''Systems Engineering Handbook'' (2015: 47-83, 104-121). | ||

| + | |The knowledge area of the ISEBoK (2021: 53-46) focuses on the design of products and the product life cycle. It closely parallels the technical processes for system design and development of SEBoK. | ||

| + | |- | ||

| + | |Systems Deployment | ||

| + | |Systems engineers participate in defining requirements, defining the architecture, and verification and validation of deployment systems needed to the deploy the system of interest, e.g., special transport equipment such as the Shuttle Carrier Aircraft (SCA) that NASA used to transport Space Shuttle orbiters. (Jenkins 2000) | ||

| + | |Industrial engineers are more focused on air, ground, water, and intermodal logistics to include transportation and distribution of systems and products. | ||

| + | |- | ||

| + | |Updates, Upgrades, Modernization | ||

| + | |Systems engineers are involved defining requirements, defining the architecture, and verification and validation of updates, upgrades, and modernization of systems. One way that this has been explained is that a second iteration of the systems engineering V-model is completed as the systems remains in service while a system change project is implemented (Ven, Talik, and Hulse 2012). | ||

| + | |Industrial engineers are involved in manufacturing processes and supporting operations of systems to provide goods and services. Industrial engineers can help identify the need for updates, upgrades, and modernization of manufacturing and service processes and work with engineering managers, systems engineers, and design engineers to provide improved capabilities. | ||

| + | |- | ||

| + | |Service Life Extension | ||

| + | |Systems engineers are involved in service life extension efforts in the same way that they are involved in updates, upgrades, and modernization of systems. | ||

| + | |Industrial engineers are involved in service life extension efforts in the same way that they are involved in updates, upgrades, and modernization of systems. | ||

| + | |- | ||

| + | |System Maintenance | ||

| + | |Systems engineers participate in defining requirements for maintenance across the life cycle of the system, determine the impact of maintenance constraints on the system requirements and the system architecture (Walden, et al. 2015: 97-98). | ||

| + | |Industrial engineers provide engineering support to production processes maintenance and system maintenance to sustain operation of production and service processes and systems. | ||

| + | |- | ||

| + | |Logistics | ||

| + | |Systems engineers participate in defining requirements for logistics across the life cycle of the system, determine the impact of maintenance constraints on the system requirements and the system architecture (Walden, et al. 2015: 97-98). | ||

| + | |Industrial engineers are very involved in logistics planning and operations including supply chain management, transportation, and distribution. | ||

| + | |- | ||

| + | |Disposal and Retirement | ||

| + | |Systems engineers identify requirements, define the architecture, and verification and validation of disposal and retirement needed to the disposition or retire the system of interest, e.g., nuclear material stabilization processes and equipment needed to disposition fissile nuclear materials to enable shutdown of the nuclear production facilities (Kenley, et al. 1999). | ||

| + | |Industrial engineers plan for disposal and retirement as part of their product design process. Increasingly, industrial engineers must consider environmental impact and sustainability issues. | ||

| + | |} | ||

| − | == | + | = Roles in a System Life Cycle = |

| + | Systems engineers and industrial engineers play important roles in a system life cycle. Figure 4 modifies a format from Buede and Miller (2016). It shows the system life cycle stages and, based on analysis in the previous section, identifies and summarizes the major roles of systems engineers, industrial engineers, and design engineers. Some processes have been aggregated to simplify the figure. | ||

| + | |||

| + | [[File:SE&IE_lifecycle_view.png|thumb|center|700px|''Figure 4. Roles in a System Life Cycle.'' (SEBoK Original, adapted from Driscoll 2011)]] | ||

| − | + | = Summary = | |

| + | In summary: | ||

| − | + | * The SEBoK ''SE and Management'' Part is based on an ISO standard. IE has several related ISO standards. IISE does not link its body of knowledge to standards. | |

| + | * The SEBoK is more process focused, while IISEBoK focuses more on concepts and techniques. | ||

| + | * SE and IE have overlapping bodies of knowledge. | ||

| + | * The SEBoK and INCOSE's SE Handbook align with the system life cycle. The IISEBoK does not have an analogous organizing structure. | ||

| + | * Systems engineers and industrial engineers both play important roles in the system life cycle with some overlapping responsibilities. | ||

| − | + | = References = | |

| + | ===Works Cited=== | ||

| + | Buede, D.M, W.D. Miller. 2016. ''The Engineering Design of Systems: Models and Methods''. Hoboken, NJ, USA: Wiley. | ||

| − | + | DA PAM 70-3. 2008. ''Army Acquisition Procedures''. Pamphlet, January 28, 2008, Washington, DC, USA: Department of the Army. | |

| − | + | Environmental Protection Agency. ''Guidelines for Preparing Economic Analyses''. Accessed November 19, 2021. Available at https://www.epa.gov/environmental-economics/guidelines-preparing-economic-analyses. | |

| − | + | IISE. 2021. ''IISE Body of Knowledge''. Institute of Industrial and Systems Engineers (IISE). Accessed May 13, 2022. Available at https://www.iise.org/BodyofKnowledge. | |

| − | + | Institute of Industrial and Systems Engineers website. ''Origins of IISE.'' Accessed November 13, 2021. Available at https://www.iise.org/details.aspx?id=295. | |

| − | + | International Council on Systems Engineering (INCOSE) website. ''What is systems engineering?'' Accessed February 17, 2022. Available at https://www.incose.org/about-systems-engineering/system-and-se-definition/systems-engineering-definition. | |

| − | + | International Organization for Standardization, standards website. Accessed November 14, 2021. Available at https://www.iso.org/standards.html. | |

| − | + | ISO/IEC/IEEE 15288, 2015. ''Systems and software engineering-System life cycle processes''. Geneva, Switzerland: International Organization for Standardization. | |

| − | + | Jenkins, D.R. 2000. ''Boeing 747-100/200/300/sp.'' Airliner tech series, version 6. North Branch, MN, US: Specialty Press Publishers and Wholesalers. | |

| − | + | Kenley, B., B. Scott, B. Seidel, D. Knecht, F. Southworth, K. Osborne, N. Chipman, and T.A. Creque. 1999. "Program to Stabilize Nuclear Materials as Managed by the Plutonium Focus Area." Proceedings of Waste Management 1999. Tucson, AZ, US. | |

| − | + | Levis, A.H. and L.W. Wagenhals. 2000. "C4ISR architectures: I. Developing a Process for C4ISR Architecture Design" ''Systems Engineering.'' 3(4): 225-247. | |

| − | + | Raz, A.K., C.R. Kenley, and D.A. DeLaurentis. 2018, "System Architecting and Design Space Characterization". ''Systems Engineering.'' 21(3): 227-242. | |

| − | |||

| − | |||

| − | |||

Salvendy, G. (ed.) 2001. ''[[Handbook of Industrial Engineering, Technology and Operations Management]],'' 3rd ed. Hoboken, NJ, USA: John Wiley & Sons, Inc. | Salvendy, G. (ed.) 2001. ''[[Handbook of Industrial Engineering, Technology and Operations Management]],'' 3rd ed. Hoboken, NJ, USA: John Wiley & Sons, Inc. | ||

| − | + | Van De Ken, M., J. Talik, and J. Hulse. 2012. "An Introduction to Applying Systems Engineering to In-Service Systems," Proceedings of the 2012 INCOSE International Symposium. 22(1):879-894. Rome, Italy. Accessed May 25, 2023. Available at https://doi.org/10.1002/j.2334-5837.2012.tb01377.x. | |

| − | + | Wagenhals, L.W., S. Haider, and A.H. Levis. 2003. "Synthesizing Executable Models of Object-Oriented Architectures." ''Systems Engineering,'' 6(4): 266-300. | |

| − | + | Wagenhals, L.W., I. Shin, D. Kim, and A.H. Levis. 2000. "C4ISR architectures: II. A Structured Analysis Approach for Architecture Design." ''Systems Engineering,'' 3(4): 248-287. | |

| − | |||

| − | + | Walden, D.D., G.J. Roedler, K.J. Forsberg, R.D. Hamelin, and T.M. Shortell (ed.). 2015. ''INCOSE'' ''Systems Engineering Handbook: A Guide for System Life Cycle Processes and Activities,'' 4<sup>th</sup> Edition. Hoboken, NJ, USA: Wiley. | |

| − | + | Wymore, A.W. 1993. ''Model-Based Systems Engineering: An Introduction to The Mathematical Theory of Discrete Systems and to The Tricotyledon Theory of System Design.'' Boca Raton, FL, USA: CRC Press. | |

| − | + | Zandin, K.B. (ed.). 2001. ''[[Maynard's Industrial Engineering Handbook]]'', 5th ed. New York, NY, USA: McGraw-Hill. | |

| − | === | + | === Primary References === |

| − | + | Salvendy, G. (ed.) 2001. ''[[Handbook of Industrial Engineering, Technology and Operations Management]],'' 3rd ed. Hoboken, NJ, USA: John Wiley & Sons, Inc. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | - | + | Zandin, K.B. (ed.). 2001. ''[[Maynard's Industrial Engineering Handbook]]'', 5th ed. New York, NY, USA: McGraw-Hill. |

| − | <center>[[ | + | === Additional References === |

| + | none.<center>[[Further Insights into Geospatial/Geodetic Engineering|< Previous Article]] | [[Related Disciplines|Parent Article]] | [[Systems Engineering and Project Management|Next Article >]]</center> | ||

| − | <center>'''SEBoK v. 2. | + | <center>'''SEBoK v. 2.9, released 20 November 2023'''</center> |

[[Category:Part 6]][[Category:Knowledge Area]] | [[Category:Part 6]][[Category:Knowledge Area]] | ||

Latest revision as of 22:27, 18 November 2023

Lead Author: Gregory S. Parnell, Contributing Authors: C. Robert Kenley, Eric Specking, Ed Pohl

Systems Engineering (SE) overlaps with many fields, such as Industrial Engineering (IE), Engineering Management, Operations Research, Project Management, and Design Engineering. In fact, the main Industrial Engineering body of knowledge, called the Industrial and Systems Engineering Body of Knowledge (ISEBoK) (IISE 2021), includes the word "systems" in its title and includes a section on systems design and engineering, which references the SEBoK. This article describes the similarities and differences between SE and IE based upon their respective standards, handbooks, and bodies of knowledge. Based on this assessment, this article describes potential roles that systems engineers and industrial engineers perform during a system’s life cycle.

Introduction

When systems engineers and industrial engineers are in the same organization, they have different roles and responsibilities. While job titles vary by organization, many organizations have individuals that perform both SE and IE activities. This article tries to help systems engineers and industrial engineers better understand the different perspectives of the fields and the knowledge needed to meet the needs of their organizations and customers. The article compares the use of international standards and the contents of the bodies of knowledge for SE and IE.

Systems Engineering

The International Council on Systems Engineering (INCOSE) is a “not-for-profit membership organization founded to develop and disseminate the interdisciplinary principles and practices that enable the realization of successful systems.” INCOSE defines systems engineering as

a transdisciplinary and integrative approach to enable the successful realization, use, and retirement of engineered systems, using systems principles and concepts, and scientific, technological, and management methods. (INCOSE 2021)

Here, the terms “engineering” and “engineered” are used in their widest sense: “the action of working artfully to bring something about.” “Engineered systems” may be composed of any or all of people, products, services, information, processes, and natural elements.

INCOSE aligns its SE Handbook with ISO/IEC/IEEE 15288, System Life Cycle Processes, which focuses on processes. SEBoK Part 3 Systems Engineering and Management, which addresses the major SE technical and management processes, is also organized around 15288 process areas. In this view, SE is process oriented. Each edition of the SE Handbook aligns to an ISO/IEC/IEEE 15288 edition. Figure 1 shows the 15288 processes and how they align with the SE Handbook and SEBoK topic areas. Later in this article, these SEBoK topics and knowledge areas are compared with the knowledge areas of IE. The knowledge areas in Figure 1 align with the system life cycle if started at the top of the first column and traversed to the bottom, continued at the bottom of the second column and traversed to the top, and then continued at the bottom of the third column and traversed to the top.

Industrial Engineering

The Institute of Industrial and Systems Engineers (IISE) states that it is “the only international, non-profit, professional society dedicated to advancing the technical and managerial excellence of industrial engineers.” (IISE 2021). IISE started in 1948 as the American Institute of Industrial Engineers. In 1981, the organization was renamed the Institute of Industrial Engineers to reflect its growing international membership. In 2016, the membership voted to change the name to the Institute of Industrial and Systems Engineers. This addition reflects a vote by its membership and aligns with the “changing scope of the profession that, while keeping its industrial base, has seen more industrial and systems engineers working with large scale integrated systems in a variety of sectors”.

At the turn of this century, industrial engineering was well reflected in two prominent publications: Handbook of Industrial Engineering (Salvendy 2001) and the fifth edition of Maynard's Industrial Engineering Handbook (Zandin 2001). Salvendy (2001) stated that industrial engineers are trained to design and analyze the components of which man-machine systems are composed. They bring together individual elements that are designed via other engineering disciplines and properly synergize these subsystems together with the people components for a completely integrated man-machine system. Industrial engineers are focused on the improvement of any system that is being designed or evaluated. They make individual human tasks more productive and efficient by optimizing flow, eliminating unnecessary motions, utilizing alternate materials to improve manufacturing, improving the flow of product through processes, and optimizing the configuration of workspaces. Fundamentally, the industrial engineer is charged with reducing costs and increasing profitability through ensuring the efficient use of human, material, physical, and/or financial resources.

The view of IE has evolved over the last two decades. IISE developed the IISE Body of Knowledge in 2021 (IISE 2021). The sixth edition of Maynard's Industrial Engineering Handbook (Zandin 2022) is expected to be published in 2022. The IISEBoK has 14 knowledge areas, as shown in Figure 2. The first 13 knowledge areas identify the Industrial Engineering knowledge. The fourteenth is Systems Design and Engineering, which references the SEBoK. The IISEBoK provides a short description of each knowledge area, a detailed outline of knowledge area topics, and a list of references. The IISEBoK does not use standards as its foundation. In fact, the Standard Practice for Systems Safety (MIL-STD-0-882D) is the only standard cited in the reference section. IISE does not currently have a handbook developed by or for the Institute, although Zandin (2022) is expected to align with the IISEBoK.

The 14 topic areas included in the IISEBoK could be tied to many international standards even though the IISEBoK does not use standards as its foundation or provide references to standards in most of its topic areas.

Venn Diagram Comparison

This section compares the two bodies of knowledge. Figure 3 is a Venn Diagram that identifies knowledge areas that are usually performed by systems engineers, ones usually performed by industrial engineers, and ones that are used by both disciplines.

There are 11 primarily SE knowledge areas, 7 primarily IE knowledge areas, and 12 overlapping knowledge areas. Table 1 provides some illustrative examples of the differences in SE and IE focus in the overlapping knowledge areas.

| Knowledge Area | Systems Engineering Focus | Industrial Engineering Focus |

| 2. Operations Research (OR) and Analysis | OR and analysis is used in systems analysis to assess system performance and to evaluate system designs (Levis and Wagenhals 2000; Wagenhals, Shin, Kim, and Levis 2000; Wagenhals, Haider, and Levis 2003; Raz, Kenley, and DeLaurentis 2018) | OR and analysis is used to optimize operations, maintenance, and logistics. OR is also used to evaluate and optimize manufacturing systems. |

| 5. Quality & Reliability Engineering | Quality and reliability requirements are treated as system-wide performance requirements (Buede and Miller 2016: 157-159; Wymore 1993: 401) that are assessed at the systems level. One example is availability, A0, which measures the degree to which a system is either operating or can operate at any time when used in its typical operational and support environment. (DA PAM 70-3 2008: 87) | Quality and reliability are used to evaluate and improve the manufacturing process of goods and services. Reliability is also used to evaluate and improve system operations. |

| 6. Ergonomics and Human Factors | Ergonomics and human factors are considerations in assessing the potential usability of a system for end-users in an operational environment. According to Buede and Miller (2016: 180), “Performance elements of usability are ease of learning (learnability), ease of use (efficiency), ease of remembering (memorability), error rate, and subjectively pleasing (satisfaction).” | Ergonomics and human factors are used to assess and improve manufacturing and operational processes. They are also used to assess and improve the actual usability of products and services. |

| 9. Engineering Management | Engineering managers and SEs work with program managers to develop and improve new products and services. | Engineering managers and IEs support operations managers responsible for manufacturing processes and the operation of systems providing products and services. |

| 11. Information Engineering | Information Engineering is critical to the development of new products and services that are increasingly software intensive. Information engineering is relevant for model-based systems engineering software tools and databases, requirements management software tools and databases, and overall configuration management of the systems design and requirements baseline. | The Information Engineering knowledge area focuses on using data in information systems to facilitate decision-making and business communication. |

| 13. Product Design and Development | SE focuses on the design of systems that provide products and services and the system life cycle. SE includes the technical processes for system design and verification and the technical management processes for project planning, assessment, and control; risk management; and decision management in the Systems Engineering Handbook (2015: 47-83, 104-121). | The knowledge area of the ISEBoK (2021: 53-46) focuses on the design of products and the product life cycle. It closely parallels the technical processes for system design and development of SEBoK. |

| Systems Deployment | Systems engineers participate in defining requirements, defining the architecture, and verification and validation of deployment systems needed to the deploy the system of interest, e.g., special transport equipment such as the Shuttle Carrier Aircraft (SCA) that NASA used to transport Space Shuttle orbiters. (Jenkins 2000) | Industrial engineers are more focused on air, ground, water, and intermodal logistics to include transportation and distribution of systems and products. |

| Updates, Upgrades, Modernization | Systems engineers are involved defining requirements, defining the architecture, and verification and validation of updates, upgrades, and modernization of systems. One way that this has been explained is that a second iteration of the systems engineering V-model is completed as the systems remains in service while a system change project is implemented (Ven, Talik, and Hulse 2012). | Industrial engineers are involved in manufacturing processes and supporting operations of systems to provide goods and services. Industrial engineers can help identify the need for updates, upgrades, and modernization of manufacturing and service processes and work with engineering managers, systems engineers, and design engineers to provide improved capabilities. |

| Service Life Extension | Systems engineers are involved in service life extension efforts in the same way that they are involved in updates, upgrades, and modernization of systems. | Industrial engineers are involved in service life extension efforts in the same way that they are involved in updates, upgrades, and modernization of systems. |

| System Maintenance | Systems engineers participate in defining requirements for maintenance across the life cycle of the system, determine the impact of maintenance constraints on the system requirements and the system architecture (Walden, et al. 2015: 97-98). | Industrial engineers provide engineering support to production processes maintenance and system maintenance to sustain operation of production and service processes and systems. |

| Logistics | Systems engineers participate in defining requirements for logistics across the life cycle of the system, determine the impact of maintenance constraints on the system requirements and the system architecture (Walden, et al. 2015: 97-98). | Industrial engineers are very involved in logistics planning and operations including supply chain management, transportation, and distribution. |

| Disposal and Retirement | Systems engineers identify requirements, define the architecture, and verification and validation of disposal and retirement needed to the disposition or retire the system of interest, e.g., nuclear material stabilization processes and equipment needed to disposition fissile nuclear materials to enable shutdown of the nuclear production facilities (Kenley, et al. 1999). | Industrial engineers plan for disposal and retirement as part of their product design process. Increasingly, industrial engineers must consider environmental impact and sustainability issues. |

Roles in a System Life Cycle

Systems engineers and industrial engineers play important roles in a system life cycle. Figure 4 modifies a format from Buede and Miller (2016). It shows the system life cycle stages and, based on analysis in the previous section, identifies and summarizes the major roles of systems engineers, industrial engineers, and design engineers. Some processes have been aggregated to simplify the figure.

Summary

In summary:

- The SEBoK SE and Management Part is based on an ISO standard. IE has several related ISO standards. IISE does not link its body of knowledge to standards.

- The SEBoK is more process focused, while IISEBoK focuses more on concepts and techniques.

- SE and IE have overlapping bodies of knowledge.

- The SEBoK and INCOSE's SE Handbook align with the system life cycle. The IISEBoK does not have an analogous organizing structure.

- Systems engineers and industrial engineers both play important roles in the system life cycle with some overlapping responsibilities.

References

Works Cited

Buede, D.M, W.D. Miller. 2016. The Engineering Design of Systems: Models and Methods. Hoboken, NJ, USA: Wiley.

DA PAM 70-3. 2008. Army Acquisition Procedures. Pamphlet, January 28, 2008, Washington, DC, USA: Department of the Army.

Environmental Protection Agency. Guidelines for Preparing Economic Analyses. Accessed November 19, 2021. Available at https://www.epa.gov/environmental-economics/guidelines-preparing-economic-analyses.

IISE. 2021. IISE Body of Knowledge. Institute of Industrial and Systems Engineers (IISE). Accessed May 13, 2022. Available at https://www.iise.org/BodyofKnowledge.

Institute of Industrial and Systems Engineers website. Origins of IISE. Accessed November 13, 2021. Available at https://www.iise.org/details.aspx?id=295.

International Council on Systems Engineering (INCOSE) website. What is systems engineering? Accessed February 17, 2022. Available at https://www.incose.org/about-systems-engineering/system-and-se-definition/systems-engineering-definition.

International Organization for Standardization, standards website. Accessed November 14, 2021. Available at https://www.iso.org/standards.html.

ISO/IEC/IEEE 15288, 2015. Systems and software engineering-System life cycle processes. Geneva, Switzerland: International Organization for Standardization.

Jenkins, D.R. 2000. Boeing 747-100/200/300/sp. Airliner tech series, version 6. North Branch, MN, US: Specialty Press Publishers and Wholesalers.

Kenley, B., B. Scott, B. Seidel, D. Knecht, F. Southworth, K. Osborne, N. Chipman, and T.A. Creque. 1999. "Program to Stabilize Nuclear Materials as Managed by the Plutonium Focus Area." Proceedings of Waste Management 1999. Tucson, AZ, US.

Levis, A.H. and L.W. Wagenhals. 2000. "C4ISR architectures: I. Developing a Process for C4ISR Architecture Design" Systems Engineering. 3(4): 225-247.

Raz, A.K., C.R. Kenley, and D.A. DeLaurentis. 2018, "System Architecting and Design Space Characterization". Systems Engineering. 21(3): 227-242.

Salvendy, G. (ed.) 2001. Handbook of Industrial Engineering, Technology and Operations Management, 3rd ed. Hoboken, NJ, USA: John Wiley & Sons, Inc.

Van De Ken, M., J. Talik, and J. Hulse. 2012. "An Introduction to Applying Systems Engineering to In-Service Systems," Proceedings of the 2012 INCOSE International Symposium. 22(1):879-894. Rome, Italy. Accessed May 25, 2023. Available at https://doi.org/10.1002/j.2334-5837.2012.tb01377.x.

Wagenhals, L.W., S. Haider, and A.H. Levis. 2003. "Synthesizing Executable Models of Object-Oriented Architectures." Systems Engineering, 6(4): 266-300.

Wagenhals, L.W., I. Shin, D. Kim, and A.H. Levis. 2000. "C4ISR architectures: II. A Structured Analysis Approach for Architecture Design." Systems Engineering, 3(4): 248-287.

Walden, D.D., G.J. Roedler, K.J. Forsberg, R.D. Hamelin, and T.M. Shortell (ed.). 2015. INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and Activities, 4th Edition. Hoboken, NJ, USA: Wiley.

Wymore, A.W. 1993. Model-Based Systems Engineering: An Introduction to The Mathematical Theory of Discrete Systems and to The Tricotyledon Theory of System Design. Boca Raton, FL, USA: CRC Press.

Zandin, K.B. (ed.). 2001. Maynard's Industrial Engineering Handbook, 5th ed. New York, NY, USA: McGraw-Hill.

Primary References

Salvendy, G. (ed.) 2001. Handbook of Industrial Engineering, Technology and Operations Management, 3rd ed. Hoboken, NJ, USA: John Wiley & Sons, Inc.

Zandin, K.B. (ed.). 2001. Maynard's Industrial Engineering Handbook, 5th ed. New York, NY, USA: McGraw-Hill.

Additional References

none.