Difference between revisions of "Systems Engineering and Management"

m (Text replacement - "SEBoK v. 2.9, released 13 November 2023" to "SEBoK v. 2.9, released 20 November 2023") |

|||

| (241 intermediate revisions by 22 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | ---- | |

| + | '''''Lead Authors:''''' Jeffrey Carter and Caitlyn Singam | ||

| + | ---- | ||

| + | Systems Engineering and Management (SE&M) articles provide system lifecycle best practices for defining and executing interdisciplinary processes to ensure that customer needs are satisfied with a technical performance, schedule, and cost compliant solution. The figure below depicts the context of SE&M processes and practices guidance within the SEBoK. | ||

| − | + | [[File:SEBoK_Context_Diagram_Inner_P3_Ifezue_Obiako.png|centre|thumb|600x600px|'''Figure 1: SEBoK Part 3 SE&M Context [SEBoK Original]''' for more detail see [[Structure of the SEBoK]]]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The SE&M materials are currently being updated to provide system design practitioners with Digital Engineering [DE] and Model-Based Systems Engineering [MBSE] implementation guidance employing the Systems Modeling Language (SysML). | |

| − | + | * DE conducts Agile system-software development based on industry open standards by employing MBSE. | |

| + | * MBSE develops and integrates SysML design models with simulation capabilities for cross-domain collaboration across the lifecycle. | ||

| + | * SysML is an industry standard graphical notation with formal semantics (meaning) to define system requirements, constraints, allocations, behavior and structure characteristics | ||

| − | + | ==SE&M Knowledge Areas== | |

| + | The SE&M articles are organized into the following Knowledge Areas [KAs]. | ||

| + | *[[Systems Engineering STEM Overview]] | ||

| + | *[[Model-Based Systems Engineering (MBSE)]] | ||

| + | *[[Systems Lifecycle Approaches]] | ||

| + | *[[System Lifecycle Models]] | ||

| + | *[[Systems Engineering Management]] | ||

| + | *[[Business and Mission Analysis]] | ||

| + | *[[Stakeholder Needs Definition]] | ||

| + | *[[System Architecture Definition]] | ||

| + | *[[Detailed Design Definition]] | ||

| + | *[[System Analysis]] | ||

| + | *[[System Realization]] | ||

| + | *[[System Implementation]] | ||

| + | *[[System Integration]] | ||

| + | *[[System Verification]] | ||

| + | *[[System Transition]] | ||

| + | *[[System Validation]] | ||

| + | *[[System Operation]] | ||

| + | *[[System Maintenance]] | ||

| + | *System Specialty Engineering | ||

| + | *[[Logistics]] | ||

| + | *[[Service Life Management]] | ||

| + | *[[Systems Engineering Standards]] | ||

| + | The SE&M articles provide exemplar processes and practices which are tailorable for an engineering organization to satisfy strategic business goals and individual project objectives including: | ||

| − | The | + | *How engineering conducts system development |

| + | *The purpose of each engineering artifact generated | ||

| + | *How systems are integrated, and requirements verified | ||

| + | *How new product designs are transitioned to production operations | ||

| + | *How the resulting system is employed and sustained to satisfy customer needs | ||

| − | == | + | ==Systems Engineering & Management Overview== |

| + | The role of Systems Engineering [SE] is to define system requirements, constraints, allocations, behavior and structure characteristics to satisfy customer needs. The system is defined in terms of hierarchical structural elements and their behavior interactions. The interactions include the exchange of data, energy, force, or mass which modifies the state of the cooperating elements resulting in emergent, discrete, or continuous behaviors. The behaviors are at sequential levels of aggregation [bottoms-up] or decomposition [top-down] to satisfy requirements, constraints, and allocations. SE collaborates within an integrated product team with electrical, mechanical, software, and specialty engineering to define the subsystem and component detailed design implementations to develop a holistic technical solution. | ||

| − | + | SE has traditionally applied intuitive domain-specific practices emphasizing processes and procedures with good writing skills to manually organize information in a disparate collection of documents including textual system requirement specifications, analysis reports, system design descriptions, and interface specifications. Traditional SE is often referred to as a document-centric approach. System design practitioners have cultivated model-based techniques since the late 1990s to facilitate communications, manage design complexity, improve product quality, enhance knowledge capture and reuse. MBSE is defined as the formalized application of graphical modeling with precise semantic definitions for operational analysis, requirements definition, system design development and verification activities beginning in the conceptual phase and continuing throughout later lifecycle phases [INCOSE, 2015]. MBSE conducts system development employing an engineering ecosystem consisting of commercially available tools to create a system design model with SysML compliant semantics that represents the system requirements, constraints, allocations, behavior and structure characteristics. The system design model provides an Authoritative Source of Truth [ASoT] for the project technical baseline with integrated end-to-end simulation capabilities to evaluate system key performance parameters in digital computing environments. MBSE includes the creation, development, and utilization of digital design models with domain product-specific analyses including aerospace, automobile, consumer, defense, and software. | |

| − | [ | + | The recent adoption of DE practices [Roper, 2020] broadens the MBSE transformation based on the following principals: |

| − | + | * Agile System and Software Development to prioritize capability development and respond to evolving threats, environments, and challenges. | |

| + | * Modular Open System Approach [MOSA] to develop product-lines based on industry standards that can adapt to evolving customer needs with new, modified, and existing [reuse] capabilities. | ||

| + | * Digital Engineering [DE] to develop, integrate, and employ MBSE design models with simulation capabilities to realistically emulate systems in digital computing environments for cross-domain collaboration across the system design development, verification, production, and sustainment lifecycle. | ||

| − | + | The system design model includes functional, logical, and physical system design representations with capabilities that are integrated with electrical, mechanical, software, and specialty design disciplines for system functional and performance assessments. Design model scripts can export functional (SSS, B1, B2, B5) specifications, interface (IRS, ICD, IDD) specifications, design & requirements traceability reports, and design descriptions (SADD, SSDD, SWDD). The integrated simulations provide a digital twin with digital threads of system key performance parameters to evaluate design alternatives in digital computing environments to discover and resolve design defects before the expense of producing physical prototypes. | |

| − | + | * Digital threads are analytical frameworks providing end-to-end system simulations to evaluate logical operations and key performance parameters in digital computing environments by exchanging information between different engineering modeling tools across the lifecycle. Evaluation of the digital thread simulations ensure that requirements, interactions, and dependencies are commonly understood across engineering disciplines. Design changes are automatically reflected in all design model usages to assess compliance, with any issue(s) flagged for corrective action. | |

| + | * Digital twins are authoritative representations of physical systems including the digital thread end-to-end connections with all the data, models, and infrastructure needed to define and optimize a system’s lifecycle digitally. Digital twins enable project team collaboration, system simulation functional performance assessments, design change impact evaluations, and product-line management reuse libraries | ||

| − | + | MBSE enhances the ability to capture, analyze, share, and manage authoritative information associated with the complete specification of a product compared to traditional document-based approaches. MBSE provides the capability to consolidate information in an accessible, centralized source, enabling partial or complete automation of many systems engineering processes, and facilitating interactive representation of system components and behaviors. The legacy SE&M materials are all impacted by the adoption of MBSE practices, and the SEBoK is updating its materials accordingly to reflect best practices and principles in an integrated model-based engineering environment. The updated materials to specify system behavior and structure characteristics with traceability to the associated requirements are organized in accordance with the ISO/IEC/IEEE-15288:2015 ''Systems Lifecycle Processes'' Standard shown in the figure below. | |

| − | + | [[File:15288_Standard_Outline_-_Model.png|thumb|center|750px|'''Figure 2.''' ISO/IEC/IEEE-15288:2015 Standard Outline (SEBoK Original)]] | |

| − | + | Figure 3 depicts a generic example of the model-based system design process. The approach is consistent with INCOSE’s Systems Engineering Handbook guidance with the addition of a system design model repository to manage the project technical baseline. The MBSE design process is independent of any specific design methodology (e.g., structured analysis, object orientated, etc.) employed. Each design model element has a single definition with multiple instantiations on various diagrams depicting system structure and behavior characteristics including traceability to the associated requirements. The model-based design process may be tailored for projects dependent on the domain-area, development, and lifecycle approaches. | |

| − | + | [[File:Model-Based_System_Design_Process_Part3.png|thumb|center|600px|''Figure 3: Model-Based System Engineering Process.'' (SEBoK Original)]] | |

| − | + | Product domain-area system design knowledge and expertise are still mandatory with the implementation of an MBSE approach, which employs integrated modeling tools instead of legacy drawing tools (e.g., Powerpoint, Visio), textual-based specifications (e.g., DOORS), and engineering analysis reports and design descriptions (Word). | |

| − | + | The SE&M model-based system design guidance enables a multi-disciplinary team to manage a project’s technical baseline within a single, consistent, and unambiguous system design model. The integrated MBSE design model contains system functional and logical representations with the physical detailed design implementation to specify, analyze, design, and verify that requirements are satisfied. The guidance defines conventions for developing design models to specify system behavior and structure characteristics with traceability to the project’s requirements. The design models provide a digital authoritative source of truth information repository for a project’s technical baseline. Model simulation with test cases facilitate initial design verification in digital computing environments to discover and resolve design defects before incurring the expense of producing physical prototypes. | |

| − | The | + | MBSE practices transform SE from the current document-based approach to employing computer aided design tools comparable to the evolution of the EE, ME, SW, and SP disciplines years ago. The value-added benefit is employment of integrated modeling tools instead of traditional static drawing tools [e.g., PowerPoint, Visio] for product development, integration, and verification across the system lifecycle. |

| + | The SE&M model-based system design guidance provides MBSE best practices for implementing a digital engineering strategy to develop system design models for specifying and simulating behavior / structure characteristics with traceability to the associated requirements based on the following principles: | ||

| + | #Develop, integrate, and employ digital system design models for cross-domain collaboration throughout the product lifecycle [i.e., engineering development, production, and sustainment]. | ||

| + | #Manage product-lines based on industry open standards with libraries of customized variants adapted for customers with new, modified, and existing [reuse] system design capabilities. | ||

| + | #Maintain a digital authoritative source of truth information repository for each product variant’s approved technical baseline throughout the product lifecycle to facilitate collaboration and inform decision making. | ||

| + | #Conduct model simulations with verification test cases to evaluate system behavior and structure in digital computing environments to discover design defects before the expense of producing physical prototypes. | ||

| + | #Define digital threads of technical key performance parameters and synchronize information across SE, EE, ME, SW, and SP design modeling tools to ensure system requirements, interactions, and dependencies are commonly understood. Design changes are automatically reflected in all model usages across engineering discipline tools and assessed for compliance, with any issue(s) flagged for corrective action. | ||

| + | #Utilize “Agile” development processes to provide consistent methods for developing system design models and identifying digital threads for data synchronization across engineering disciplines within the integrated model-based engineering environment. | ||

| − | + | The SE&M model-based system design approach has a theoretical scientific foundation based on the system phenomenon defined by Hamilton’s Principle: a system is composed of hierarchical elements which interact by exchanging data, energy, force, or mass to modify the state of cooperating elements resulting in emergent, discrete, or continuous behaviors at progressive levels of aggregation or decomposition as shown in Figure 4. | |

| + | [[File:The_System_Phenomenon.png|thumb|center|750px|''Figure 4: The System Phenomenon – Hamilton’s Principle.'' (SEBoK Original)]] | ||

| − | + | ==References== | |

| + | ===Citations=== | ||

| + | OMG Systems Modeling Language [SysML®] Standard – v1.6, November 2019 | ||

| + | INCOSE. 2015. ''[[INCOSE Systems Engineering Handbook|Systems Engineering Handbook]] - A Guide for System Life Cycle Processes and Activities'', version 4.0. Hoboken, NJ, USA: John Wiley and Sons, Inc, ISBN: 978-1-118-99940-0. | ||

| − | The | + | Roper, W. 2020. ‘’There is No Spoon: The New Digital Acquisition Reality.’’ Arlington, VA: US Space Force, US Air Force, Assistant Secretary of the Air Force. 07 October 2020. Accessed May 25, 2023. Available at https://software.af.mil/wp-content/uploads/2020/10/There-Is-No-Spoon-Digital-Acquisition-7-Oct-2020-digital-version.pdf. |

| − | + | ISO/IEC/IEEE 15288:2015. ''Systems and Software Engineering -- System Life Cycle Processes''. Geneva, Switzerland: International Organization for Standardization / International Electrotechnical Commissions / Institute for Electrical and Electronics Engineers. ISO/IEC/IEEE 15288:2015. | |

| − | + | Schindel, B. 2016. “Got Phenomena? Science-Based Disciplines for Emerging Systems Challenges,” International Council on Systems Engineering (INCOSE), 2016 INCOSE International Symposium Proceedings, Edinburgh, Scotland. | |

| + | Schindel, B. 2018. “The System Phenomenon, Hamilton’s Principle, and Noether’s Theorem as a Basis for System Science,” International Council on Systems Engineering (INCOSE), 2018 INCOSE International Workshop Proceedings, Torrance, California. | ||

| − | + | ===Primary References=== | |

| + | INCOSE. 2015. ''[[INCOSE Systems Engineering Handbook|Systems Engineering Handbook]] - A Guide for System Life Cycle Processes and Activities'', version 4.0. Hoboken, NJ, USA: John Wiley and Sons, Inc, ISBN: 978-1-118-99940-0. | ||

| + | ISO/IEC/IEEE. 2015. [[ISO/IEC/IEEE 15288| Systems and Software Engineering -- System Life Cycle Processes]]. Geneva, Switzerland: International Organization for Standardization / International Electrotechnical Commissions. ISO/IEC/IEEE 15288:2015. | ||

| − | + | ===Additional References=== | |

| − | + | U.S. DOD. 2018. ‘’Digital Engineering Strategy.’’ Arlington, VA: Office of the Deputy Assistant Secretary of Defense for Systems Engineering. June 2018. | |

| − | |||

| − | |||

| − | == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Wasson, C. 2006. System Analysis, Design, and Development – Concepts, Principles, and Practices.’’ Hoboken, NJ: John Wiley & Sons. | |

| − | |||

| − | |||

| − | |||

| − | + | Madni, A. M. and Sievers, M. 2018. ''Model‐based systems engineering: Motivation, current status, and research opportunities'', Systems Engineering. 2018; 21: 172– 190. <nowiki>https://doi.org/10.1002/sys.21438</nowiki> | |

| − | + | Estefan, J. 2008. ''A Survey of Model-Based Systems Engineering (MBSE) Methodologies'', rev, B. Seattle, WA: International Council on Systems Engineering. INCOSE-TD-2007-003-02. Accessed April 13, 2015. Available at http://www.omgsysml.org/MBSE_Methodology_Survey_RevB.pdf. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

---- | ---- | ||

| − | + | <center>[[Applying the Systems Approach|< Previous Article]] | [[SEBoK Table of Contents|Parent Article]] | [[Systems Engineering STEM Overview|Next Article >]]</center> | |

| − | + | <center>'''SEBoK v. 2.9, released 20 November 2023'''</center> | |

| − | <center> | ||

| − | + | [[Category: Part 3]] | |

| − | [[Category: Part 3]][[Category:Part]] | + | [[Category:Part]] |

Latest revision as of 23:42, 18 November 2023

Lead Authors: Jeffrey Carter and Caitlyn Singam

Systems Engineering and Management (SE&M) articles provide system lifecycle best practices for defining and executing interdisciplinary processes to ensure that customer needs are satisfied with a technical performance, schedule, and cost compliant solution. The figure below depicts the context of SE&M processes and practices guidance within the SEBoK.

The SE&M materials are currently being updated to provide system design practitioners with Digital Engineering [DE] and Model-Based Systems Engineering [MBSE] implementation guidance employing the Systems Modeling Language (SysML).

- DE conducts Agile system-software development based on industry open standards by employing MBSE.

- MBSE develops and integrates SysML design models with simulation capabilities for cross-domain collaboration across the lifecycle.

- SysML is an industry standard graphical notation with formal semantics (meaning) to define system requirements, constraints, allocations, behavior and structure characteristics

SE&M Knowledge Areas

The SE&M articles are organized into the following Knowledge Areas [KAs].

- Systems Engineering STEM Overview

- Model-Based Systems Engineering (MBSE)

- Systems Lifecycle Approaches

- System Lifecycle Models

- Systems Engineering Management

- Business and Mission Analysis

- Stakeholder Needs Definition

- System Architecture Definition

- Detailed Design Definition

- System Analysis

- System Realization

- System Implementation

- System Integration

- System Verification

- System Transition

- System Validation

- System Operation

- System Maintenance

- System Specialty Engineering

- Logistics

- Service Life Management

- Systems Engineering Standards

The SE&M articles provide exemplar processes and practices which are tailorable for an engineering organization to satisfy strategic business goals and individual project objectives including:

- How engineering conducts system development

- The purpose of each engineering artifact generated

- How systems are integrated, and requirements verified

- How new product designs are transitioned to production operations

- How the resulting system is employed and sustained to satisfy customer needs

Systems Engineering & Management Overview

The role of Systems Engineering [SE] is to define system requirements, constraints, allocations, behavior and structure characteristics to satisfy customer needs. The system is defined in terms of hierarchical structural elements and their behavior interactions. The interactions include the exchange of data, energy, force, or mass which modifies the state of the cooperating elements resulting in emergent, discrete, or continuous behaviors. The behaviors are at sequential levels of aggregation [bottoms-up] or decomposition [top-down] to satisfy requirements, constraints, and allocations. SE collaborates within an integrated product team with electrical, mechanical, software, and specialty engineering to define the subsystem and component detailed design implementations to develop a holistic technical solution.

SE has traditionally applied intuitive domain-specific practices emphasizing processes and procedures with good writing skills to manually organize information in a disparate collection of documents including textual system requirement specifications, analysis reports, system design descriptions, and interface specifications. Traditional SE is often referred to as a document-centric approach. System design practitioners have cultivated model-based techniques since the late 1990s to facilitate communications, manage design complexity, improve product quality, enhance knowledge capture and reuse. MBSE is defined as the formalized application of graphical modeling with precise semantic definitions for operational analysis, requirements definition, system design development and verification activities beginning in the conceptual phase and continuing throughout later lifecycle phases [INCOSE, 2015]. MBSE conducts system development employing an engineering ecosystem consisting of commercially available tools to create a system design model with SysML compliant semantics that represents the system requirements, constraints, allocations, behavior and structure characteristics. The system design model provides an Authoritative Source of Truth [ASoT] for the project technical baseline with integrated end-to-end simulation capabilities to evaluate system key performance parameters in digital computing environments. MBSE includes the creation, development, and utilization of digital design models with domain product-specific analyses including aerospace, automobile, consumer, defense, and software.

The recent adoption of DE practices [Roper, 2020] broadens the MBSE transformation based on the following principals:

- Agile System and Software Development to prioritize capability development and respond to evolving threats, environments, and challenges.

- Modular Open System Approach [MOSA] to develop product-lines based on industry standards that can adapt to evolving customer needs with new, modified, and existing [reuse] capabilities.

- Digital Engineering [DE] to develop, integrate, and employ MBSE design models with simulation capabilities to realistically emulate systems in digital computing environments for cross-domain collaboration across the system design development, verification, production, and sustainment lifecycle.

The system design model includes functional, logical, and physical system design representations with capabilities that are integrated with electrical, mechanical, software, and specialty design disciplines for system functional and performance assessments. Design model scripts can export functional (SSS, B1, B2, B5) specifications, interface (IRS, ICD, IDD) specifications, design & requirements traceability reports, and design descriptions (SADD, SSDD, SWDD). The integrated simulations provide a digital twin with digital threads of system key performance parameters to evaluate design alternatives in digital computing environments to discover and resolve design defects before the expense of producing physical prototypes.

- Digital threads are analytical frameworks providing end-to-end system simulations to evaluate logical operations and key performance parameters in digital computing environments by exchanging information between different engineering modeling tools across the lifecycle. Evaluation of the digital thread simulations ensure that requirements, interactions, and dependencies are commonly understood across engineering disciplines. Design changes are automatically reflected in all design model usages to assess compliance, with any issue(s) flagged for corrective action.

- Digital twins are authoritative representations of physical systems including the digital thread end-to-end connections with all the data, models, and infrastructure needed to define and optimize a system’s lifecycle digitally. Digital twins enable project team collaboration, system simulation functional performance assessments, design change impact evaluations, and product-line management reuse libraries

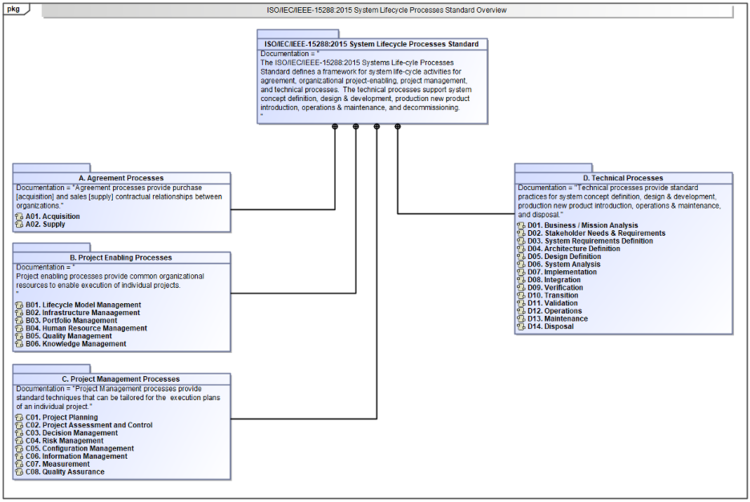

MBSE enhances the ability to capture, analyze, share, and manage authoritative information associated with the complete specification of a product compared to traditional document-based approaches. MBSE provides the capability to consolidate information in an accessible, centralized source, enabling partial or complete automation of many systems engineering processes, and facilitating interactive representation of system components and behaviors. The legacy SE&M materials are all impacted by the adoption of MBSE practices, and the SEBoK is updating its materials accordingly to reflect best practices and principles in an integrated model-based engineering environment. The updated materials to specify system behavior and structure characteristics with traceability to the associated requirements are organized in accordance with the ISO/IEC/IEEE-15288:2015 Systems Lifecycle Processes Standard shown in the figure below.

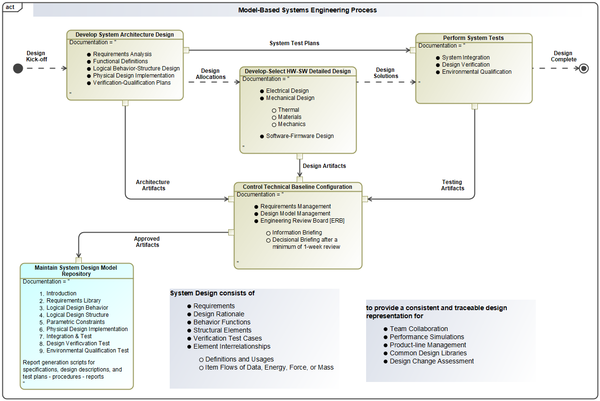

Figure 3 depicts a generic example of the model-based system design process. The approach is consistent with INCOSE’s Systems Engineering Handbook guidance with the addition of a system design model repository to manage the project technical baseline. The MBSE design process is independent of any specific design methodology (e.g., structured analysis, object orientated, etc.) employed. Each design model element has a single definition with multiple instantiations on various diagrams depicting system structure and behavior characteristics including traceability to the associated requirements. The model-based design process may be tailored for projects dependent on the domain-area, development, and lifecycle approaches.

Product domain-area system design knowledge and expertise are still mandatory with the implementation of an MBSE approach, which employs integrated modeling tools instead of legacy drawing tools (e.g., Powerpoint, Visio), textual-based specifications (e.g., DOORS), and engineering analysis reports and design descriptions (Word).

The SE&M model-based system design guidance enables a multi-disciplinary team to manage a project’s technical baseline within a single, consistent, and unambiguous system design model. The integrated MBSE design model contains system functional and logical representations with the physical detailed design implementation to specify, analyze, design, and verify that requirements are satisfied. The guidance defines conventions for developing design models to specify system behavior and structure characteristics with traceability to the project’s requirements. The design models provide a digital authoritative source of truth information repository for a project’s technical baseline. Model simulation with test cases facilitate initial design verification in digital computing environments to discover and resolve design defects before incurring the expense of producing physical prototypes.

MBSE practices transform SE from the current document-based approach to employing computer aided design tools comparable to the evolution of the EE, ME, SW, and SP disciplines years ago. The value-added benefit is employment of integrated modeling tools instead of traditional static drawing tools [e.g., PowerPoint, Visio] for product development, integration, and verification across the system lifecycle. The SE&M model-based system design guidance provides MBSE best practices for implementing a digital engineering strategy to develop system design models for specifying and simulating behavior / structure characteristics with traceability to the associated requirements based on the following principles:

- Develop, integrate, and employ digital system design models for cross-domain collaboration throughout the product lifecycle [i.e., engineering development, production, and sustainment].

- Manage product-lines based on industry open standards with libraries of customized variants adapted for customers with new, modified, and existing [reuse] system design capabilities.

- Maintain a digital authoritative source of truth information repository for each product variant’s approved technical baseline throughout the product lifecycle to facilitate collaboration and inform decision making.

- Conduct model simulations with verification test cases to evaluate system behavior and structure in digital computing environments to discover design defects before the expense of producing physical prototypes.

- Define digital threads of technical key performance parameters and synchronize information across SE, EE, ME, SW, and SP design modeling tools to ensure system requirements, interactions, and dependencies are commonly understood. Design changes are automatically reflected in all model usages across engineering discipline tools and assessed for compliance, with any issue(s) flagged for corrective action.

- Utilize “Agile” development processes to provide consistent methods for developing system design models and identifying digital threads for data synchronization across engineering disciplines within the integrated model-based engineering environment.

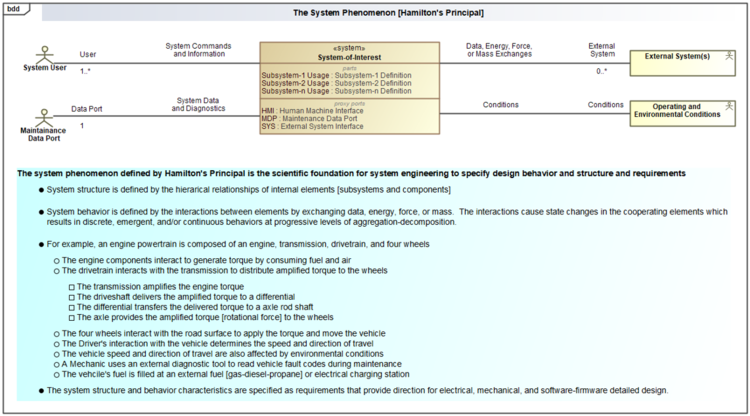

The SE&M model-based system design approach has a theoretical scientific foundation based on the system phenomenon defined by Hamilton’s Principle: a system is composed of hierarchical elements which interact by exchanging data, energy, force, or mass to modify the state of cooperating elements resulting in emergent, discrete, or continuous behaviors at progressive levels of aggregation or decomposition as shown in Figure 4.

References

Citations

OMG Systems Modeling Language [SysML®] Standard – v1.6, November 2019

INCOSE. 2015. Systems Engineering Handbook - A Guide for System Life Cycle Processes and Activities, version 4.0. Hoboken, NJ, USA: John Wiley and Sons, Inc, ISBN: 978-1-118-99940-0.

Roper, W. 2020. ‘’There is No Spoon: The New Digital Acquisition Reality.’’ Arlington, VA: US Space Force, US Air Force, Assistant Secretary of the Air Force. 07 October 2020. Accessed May 25, 2023. Available at https://software.af.mil/wp-content/uploads/2020/10/There-Is-No-Spoon-Digital-Acquisition-7-Oct-2020-digital-version.pdf.

ISO/IEC/IEEE 15288:2015. Systems and Software Engineering -- System Life Cycle Processes. Geneva, Switzerland: International Organization for Standardization / International Electrotechnical Commissions / Institute for Electrical and Electronics Engineers. ISO/IEC/IEEE 15288:2015.

Schindel, B. 2016. “Got Phenomena? Science-Based Disciplines for Emerging Systems Challenges,” International Council on Systems Engineering (INCOSE), 2016 INCOSE International Symposium Proceedings, Edinburgh, Scotland.

Schindel, B. 2018. “The System Phenomenon, Hamilton’s Principle, and Noether’s Theorem as a Basis for System Science,” International Council on Systems Engineering (INCOSE), 2018 INCOSE International Workshop Proceedings, Torrance, California.

Primary References

INCOSE. 2015. Systems Engineering Handbook - A Guide for System Life Cycle Processes and Activities, version 4.0. Hoboken, NJ, USA: John Wiley and Sons, Inc, ISBN: 978-1-118-99940-0.

ISO/IEC/IEEE. 2015. Systems and Software Engineering -- System Life Cycle Processes. Geneva, Switzerland: International Organization for Standardization / International Electrotechnical Commissions. ISO/IEC/IEEE 15288:2015.

Additional References

U.S. DOD. 2018. ‘’Digital Engineering Strategy.’’ Arlington, VA: Office of the Deputy Assistant Secretary of Defense for Systems Engineering. June 2018.

Wasson, C. 2006. System Analysis, Design, and Development – Concepts, Principles, and Practices.’’ Hoboken, NJ: John Wiley & Sons.

Madni, A. M. and Sievers, M. 2018. Model‐based systems engineering: Motivation, current status, and research opportunities, Systems Engineering. 2018; 21: 172– 190. https://doi.org/10.1002/sys.21438

Estefan, J. 2008. A Survey of Model-Based Systems Engineering (MBSE) Methodologies, rev, B. Seattle, WA: International Council on Systems Engineering. INCOSE-TD-2007-003-02. Accessed April 13, 2015. Available at http://www.omgsysml.org/MBSE_Methodology_Survey_RevB.pdf.