Technical Planning

Systems Engineering Planning is performed concurrently and collaboratively with project planning, and involves developing and integrating technical plans to achieve the technical project objectives within the resource constraints and risk thresholds. The planning needs to include the success-critical stakeholders to ensure that necessary tasks are defined with the right timing in the life cycle to manage acceptable risks levels and avoid costly omissions. As indicated in (NASA December 2007, 1-360, Section 6.1), (Caltrans and USDOT 2005, 278, Section 3.4.2), (INCOSE 2010, Section 5.1), (DAU February 19, 2010, Section 4.5.1), and (USAF 2004, Chapter 4). SE planning is intended to provide the following elements in a form that best meets the project usage preferences:

- Definition of the project from a technical perspective.

- Definition or tailoring of engineering processes, practices, methods, and supporting enabling environments to be used to develop products or services, as well as transition and implementation of the products or services, as required by agreements.

- Definition of the technical organizational, personnel, and team functions and responsibilities, as well as all disciplines required during the project life cycle.

- Input to the definition of the appropriate life cycle model or approach for the products or services.

- Definition and timing of technical reviews, product or service assessments, and control mechanisms across the life cycle, including the success criteria in terms of cost, schedule, and technical performance at identified project milestones.

- Estimation of technical cost and schedule based on the effort needed to meet the requirements, which becomes input to project cost and schedule planning.

- Determination of critical technologies and associated risks and actions needed to manage and transition the technologies.

- Identification of linkages to other project management efforts.

SE planning begins with analyzing the scope of technical work to be performed, and understanding the constraints, risks, and objectives that define and bound the solution space for the product or service. The planning includes estimating the size of the work products, establishing a schedule (or integrating the technical tasks into the project schedule), identification of risks that the planning must consider, and negotiating commitments. Iteration of these planning tasks may be necessary to establish a balanced plan with respect to cost, schedule, technical performance, and quality. The planning continues to evolve with each life cycle phase of the project. (NASA December 2007, 1-360, Section 6.1; SEI 1995, PA 12)

SE planning requires collaboration with all programmatic and technical elements of the project to ensure a comprehensive and integrated planning effort for all of the project's technical aspects. The SE planning should account for the full scope of technical activities, including system development and definition, risk management, quality management, configuration management, measurement, information management, production, verification and test, integration, validation, and deployment. The SE planning integrates all SE functions to ensure that plans, requirements, operational concepts, and architectures are consistent and feasible.

The scope of the planning can vary between planning a specific task and developing a major technical plan. The integrated planning effort will determine what level of planning and documentation of that planning is appropriate for the project. The integration of each plan with other higher level, peer, or subordinate plans is an essential part of SE planning. For the technical effort, the systems engineering management plan (SEMP), also known as the systems engineering plan (SEP), is the highest level technical plan. It is subordinate to the Project Plan, and often has a number of subordinate technical plans providing detail on specific technical focus areas.

Task planning identifies the specific work products, deliverables, and success criteria for systems engineering effort in support of integrated planning and project objectives. The success criteria are defined in terms of cost, schedule, and technical performance at identified project milestones. Detailed task planning identifies specific resource requirements (skills, equipment, facilities, dollars) as a function of time and project milestones.

SE planning is accomplished by both the acquirer and supplier. The SE planning set of activities is performed in the context of the enterprise. Enterprise activities establish and identify relevant policies and procedures for managing and executing the project management and technical effort; identifying the management and technical tasks, their interdependencies, risks and opportunities; and providing estimates of needed resources/budgets. Plans are updated and refined throughout the development process based on status updates and evolving project requirements. (SEI 2007)

SE Planning Process Overview

The SE planning process includes the following activities:

- Define the project and technical work

- Define the engineering processes, practices, methods, and supporting enabling environments

- Define the life cycle, technical reviews, assessments, and control mechanisms

- Define the technical organizational structure and resources

- Define the schedule and cost of the technical effort

- Develop plans

- Obtain commitment to the Plans

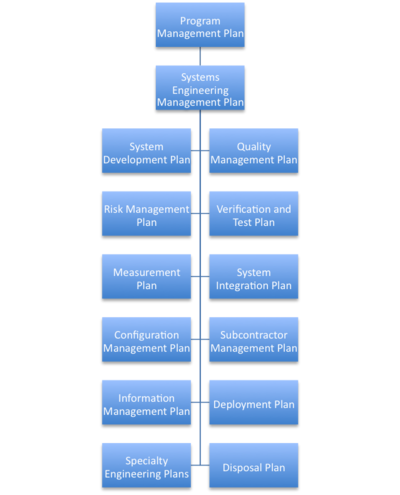

The figure below shows the SEMP and Integrated Plans.

SEMP and Integrated Plans

Linkages to Other Systems Engineering Management Topics

The project planning process is closely coupled with the Measurement, Assessment and Control, Decision Management, and Risk Management processes.

The Measurement process provides inputs for estimation models. Estimates from Planning are used inDecision Management. Systems engineering Assessment and Control processes use Planning results for setting milestones and assessing progress. Risk Management uses the Planning cost models, schedule estimates, and estimate uncertainty distributions to support quantitative risk analysis (as desired).

Additionally, Planning needs to use the outputs from Assessment and Control and Risk Management to ensure corrective actions have been accounted for in planning future activities. The planning may need to be updated based on results from technical reviews (from Assessment and Control), issues identified during the performance of Risk Management activities, or decisions made as a result of the decision management activities. (INCOSE 2010, Section 6.1)

Practical Considerations

Key pitfalls and good practices related to systems engineering planning are described in the next two sections.

Pitfalls

Some of the key pitfalls encountered in planning and performing SE Planning include:

- Significant adverse impacts on all other engineering activities from inadequate SE planning. Although it may be tempting to “save time” by rushing the planning, inadequate planning can create additional cost and schedule due to omissions in the planning, lack of integration of efforts, infeasible schedules, etc.

- Not using engineering staff members who are highly experienced, especially in similar projects, which will likely result in inadequate planning. Due to the number of concurrent and high-priority tasks during the start of a project, less experienced engineers are often assigned significant roles in the SE planning. Even though the more experienced engineering staff members are busy early in the project with many other responsibilities, it is essential to assign the SE planning tasks to those with relevant experience.

Good Practices

Some good practices, gathered from the references:

- Get technical resources from all disciplines involved in the planning process.

- Resolve schedule and resource conflicts early.

- Tasks should be as independent as possible.

- Develop dependency networks to define task interdependencies.

- Integrate risk management with the SE planning to identify areas that require special attention and/or trades.

- The amount of management reserve should be based on the risk associated with the plan.

- Use historical data for estimates and adjust for differences of the project.

- Identify lead times and account for them in the planning, e.g., development of analytical tools.

- Prepare to update plans as additional information becomes available or changes are needed.

- IPDTs are often useful to ensure adequate communications across the necessary disciplines, timely integration of all design considerations, as well as integration and test and consideration of the full range of risks that need to be addressed. Although there are some issues that need to be managed with them, IPDTs tend to break down the communication and knowledge stovepipes that often already exist.

- Additional good practices can be found in (Caltrans and USDOT 2005, 278, Section 3.4.2)(NASA December 2007, 1-360, Section 6.1; INCOSE 2010, Section 5.1; USAF 2004, Chapter 4), and (ISO/IEC/IEEE 2009, Clause 6.1).

Glossary

Acronyms

Acronym Definition

SEMP Systems Engineering Management Plan

SEP Systems Engineering Plan

References

Please make sure all references are listed alphabetically and are formatted according to the Chicago Manual of Style (15th ed). See the BKCASE Reference Guidance for additional information.

Citations

List all references cited in the article. Note: SEBoK 0.5 uses Chicago Manual of Style (15th ed). See the BKCASE Reference Guidance for additional information.

Primary References

Caltrans, and USDOT. 2005. Systems engineering guidebook for ITS, version 1.1. Sacramento, CA, USA: California Department of Transportation (Caltrans) Division of Reserach & Innovation/U.S. Department of Transportation (USDOT), SEG for ITS 1.1.

DAU. February 19, 2010. Defense acquisition guidebook (DAG). Ft. Belvoir, VA, USA: Defense Acquisition University (DAU)/U.S. Department of Defense.

ISO/IEC. 2008. Systems and software engineering - system life cycle processes. Geneva, Switzerland: International Organization for Standardization (ISO)/International Electronical Commission (IEC), ISO/IEC 15288:2008 (E).

NASA. December 2007. Systems engineering handbook. Washington, D.C.: National Aeronautics and Space Administration (NASA), NASA/SP-2007-6105.

SEI. 1995. A systems engineering capability maturity model, version 1.1. Pittsburgh, PA, USA: Software Engineering Institute (SEI)/Carnegie-Mellon University (CMU), CMU/SEI-95-MM-003.

---. 2007. Capability maturity model integrated (CMMI) for development, version 1.2, measurement and analysis process area. Pittsburgh, PA, USA: Software Engineering Institute (SEI)/Carnegie Mellon University (CMU)

INCOSE. 2010. INCOSE systems engineering handbook, version 3.2. San Diego, CA, USA: International Council on Systems Engineering (INCOSE), INCOSE-TP-2003-002-03.2.

Additional References

ISO/IEC/IEEE. 2009. Systems and software engineering - life cycle processes - project management. Geneva, Switzerland: International Organization for Standardization (ISO)/International Electronical Commission (IEC)/Institute of Electrical and Electronics Engineers (IEEE), ISO/IEC/IEEE 16326:2009(E).