Difference between revisions of "Product Systems Engineering"

| Line 119: | Line 119: | ||

ANSI/EIA. 2003. ''[[ANSI/EIA 632|Processes for Engineering a System]]''. Philadelphia, PA, USA: American National Standards Institute (ANSI)/Electronic Industries Association (EIA). [[ANSI/EIA 632]]‐1998. | ANSI/EIA. 2003. ''[[ANSI/EIA 632|Processes for Engineering a System]]''. Philadelphia, PA, USA: American National Standards Institute (ANSI)/Electronic Industries Association (EIA). [[ANSI/EIA 632]]‐1998. | ||

| − | Blanchard, B. S., and W. J. Fabrycky. 2011. ''[[Systems Engineering and Analysis]]'', 5th ed. Prentice-Hall International series in Industrial and Systems Engineering. Englewood Cliffs, NJ, USA: Prentice-Hall. | + | Blanchard, B.S., and W.J. Fabrycky. 2011. ''[[Systems Engineering and Analysis]]'', 5th ed. Prentice-Hall International series in Industrial and Systems Engineering. Englewood Cliffs, NJ, USA: Prentice-Hall. |

ISO/IEC/IEEE. 2011. ''Systems and software engineering - Architecture description''. Geneva, Switzerland: International Organization for Standardization (ISO)/International Electrotechnical Commission (IEC)/Institute of Electrical and Electronics Engineers (IEEE), ISO/IEC/IEEE 42010. | ISO/IEC/IEEE. 2011. ''Systems and software engineering - Architecture description''. Geneva, Switzerland: International Organization for Standardization (ISO)/International Electrotechnical Commission (IEC)/Institute of Electrical and Electronics Engineers (IEEE), ISO/IEC/IEEE 42010. | ||

| − | Kazman, R | + | Kazman, R, M. Klein, and P. Clements. 2000. ''ATAM; Method for Architecture Evaluation.'' Pittsburg, PA, USA: Software Engineering Institute (SEI)/Carnegie Mellon University (CMU). CMU/SEI-2000-TR-004, ESC-TR-2000-004. |

Lawson, H. 2010. ''A Journey Through the Systems Landscape''. London, UK: College Publications, Kings College, UK. | Lawson, H. 2010. ''A Journey Through the Systems Landscape''. London, UK: College Publications, Kings College, UK. | ||

| − | Magrab, E., | + | Magrab, E., S. Gupta, P. McCluskey, and P. Sandborn. 2010. ''[[Integrated Product and Process Design and Development]] - The Product Realization Process''. Boca Raton, FL, USA: CRC Press. |

| − | Martin, J.N. 1997. Systems Engineering Guidebook: A process for developing systems and products | + | Martin, J.N. 1997. ''Systems Engineering Guidebook: A process for developing systems and products,'' 1st ed. Boca Raton, FL, USA: CRC Press. |

Martin, J. 2004. "[[The Seven Samurai of Systems Engineering]]: Dealing with the Complexity of 7 Interrelated Systems." Proceedings of the International Council on Systems Engineering (INCOSE) International Symposium, Toulouse, France, 2004. | Martin, J. 2004. "[[The Seven Samurai of Systems Engineering]]: Dealing with the Complexity of 7 Interrelated Systems." Proceedings of the International Council on Systems Engineering (INCOSE) International Symposium, Toulouse, France, 2004. | ||

| − | Phillips, F. 2001. ''Market-oriented Technology Management - Innovating for Profit in Entrepreneurial Times''. Berlin, Germany: Springer-Verlag. | + | Phillips, F. 2001. ''Market-oriented Technology Management - Innovating for Profit in Entrepreneurial Times''. Berlin, Germany: Springer-Verlag. |

| − | Pugh, S. 1990. ''Total Design: Integrated Methods for Successful Product Engineering''. Upper Saddle River, NJ, USA: Prentice Hall | + | Pugh, S. 1990. ''Total Design: Integrated Methods for Successful Product Engineering''. Upper Saddle River, NJ, USA: Prentice Hall. |

Ring, J., 1998. "A Value Seeking Approach to the Engineering of Systems." Proceedings of the IEEE Conference on Systems, Man, and Cybernetics. p. 2704-2708. | Ring, J., 1998. "A Value Seeking Approach to the Engineering of Systems." Proceedings of the IEEE Conference on Systems, Man, and Cybernetics. p. 2704-2708. | ||

| − | Sage, A., and Rouse | + | Sage, A., and W. Rouse. (eds.) 1999. ''Handbook of Systems Engineering and Management''. Hoboken, NJ, USA: John Wiley and Sons, Inc. |

| − | Wasson, C. S. 2006. ''[[System Analysis, Design, and Development]]''. New York, NY, USA: John Wiley & Sons. | + | Wasson, C.S. 2006. ''[[System Analysis, Design, and Development]]''. New York, NY, USA: John Wiley & Sons. |

| − | Wheelwright, S. and Clark | + | Wheelwright, S. and K. Clark. 1992. ''Managing New Product and Process Development: Text and Cases''. Columbus, OH, USA: Free Press. |

===Primary References=== | ===Primary References=== | ||

Revision as of 23:34, 11 September 2012

Product systems engineering (PSE) is at the core of the new product development process (NPDP) that is needed to successfully develop and deploy products into different market segments. A market can be consumer based (e.g., private enterprises or general consumers) or it can be public (not-for-profit). Public markets address the strategic needs of a country or region, such as military, healthcare, educational, transportation, and energy needs. NPDP has two significantly overlapping and integrated activities:

- Systems engineering: This includes concept generation, engineering design/development, and deployment

- Market development: This includes market research, market analysis, product acceptance and market growth (diffusion), and rate of adoption

NPDP also includes manufacturability/producibility, logistics and distribution, product quality, product disposal, conformance to standards, stakeholder’s value added, and meeting customer’s expectations. The internal enterprise competence and capabilities such as customer support, sales & marketing, maintenance and repair, personnel training, etc., must also be taken into account.

To download a PDF of all of Part 4 (including this knowledge area), please click here.

Topics

Each part of the SEBoK is divided into knowledge areas (KAs), which are groupings of information with a related theme. The KAs in turn are divided into topics. This KA contains the following topics:

- Product Systems Engineering Background

- Product as a System Fundamentals

- Business Activities Related to Product Systems Engineering

- Product Systems Engineering Key Aspects

- Product Systems Engineering Special Activities

The Product Systems Engineering Background article discusses product types and the need for a product to be aligned with the business objectives of the enterprise. It also discusses the relationships between PSE and product development and technology development.

Various types of connections between product elements, and the concept of enabling systems are introduced in the Product as a System Fundamentals article. It also discusses product architecture, modeling, analysis, and integration with various specialty engineering areas.

Product launching and product offerings have close linkages to different business processes. The major linkages are to business development, marketing, product lines, quality management, project management, operations management, supply chain management, etc. These and other topics are described in the Business Activities Related to Product Systems Engineering article.

Products emerge when they are realized based upon a system definition. Realizing the system results in instances of the system that are either delivered as products to a specific acquirer (based upon an agreement) or are offered directly to buyers and users. Key Aspects of PSE are discussed in the Product Systems Engineering Key Aspects article which discusses aspects such as acquired vs. offered products, product lifecycle and adoption rates, integrated product teams (IPTs) and integrated product development teams (IPDTs), product architectures, requirements and standards, etc.

The last article, Product Systems Engineering Special Activities, covers some of the special activities carried out by PSE during the different stages from concept through product deployment.

Key Terms and Concepts

Product

A product is an artifact that is created by some person or by some process such as a manufacturing process, software source code compilation and integration, building construction, creative writing process, or data processing.

In general, a business product is defined as a thing produced by labor or effort, or the result of an act or a process. It stems from the verb produce, from the Latin prōdūce(re) (to) lead or bring forth. Since 1575, the word product has referred to anything produced, and since 1695, the word product has referred to a thing or things produced.

In economics and commerce, products belong to a broader category of goods. The economic meaning of the word product was first used by political economist Adam Smith. In marketing, a product is anything that can be offered to a market that might satisfy a want or a need. In retail industries, products are called merchandise. In manufacturing, products are purchased as raw materials and sold as finished goods. Commodities are usually raw materials, such as metals and agricultural products, but a commodity can also be anything widely available in the open market. In project management, products are the formal definitions of the project deliverables that make up or contribute to delivering the objectives of the project. In insurance, the policies are considered products offered for sale by the insurance company that created the contract.

Product System

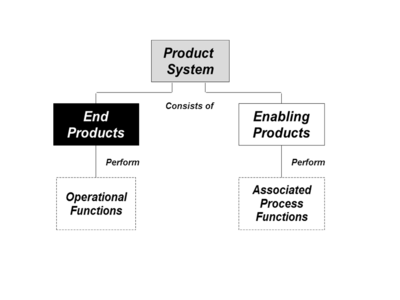

A product system is the combination of end products and the enabling products for those end products. This concept of a product system is illustrated in Figure 1. In the ANSI/EIA 632 1998 standard, just the term system is used but the scope of the standard is clearly restricted to product systems.

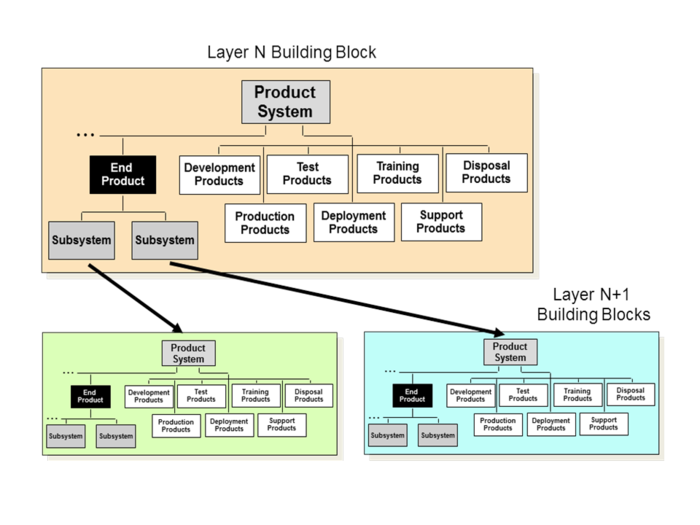

The end product can also be considered as a system with its own elements or subsystems, each of which has its own enabling products as illustrated in Figure 2. The product development process usually focuses only on the engineering of the end product. PSE is essential when the enabling products are by themselves complex or their relationship to the end product is complex. Otherwise, the use of a traditional product development process is sufficient.

Product Realization System

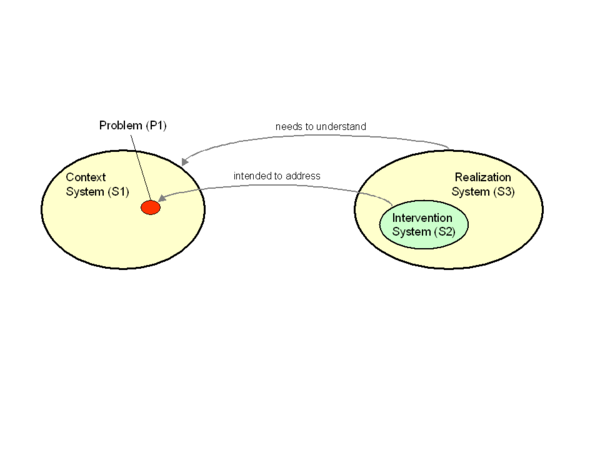

There is a related system that enables the realization of the product system, which is the product realization system. It consists of all the resources to be applied in causing the Intervention System [i.e., the product system, in this case] to be fully conceived, developed, produced, tested, and deployed (Martin 2004). Lawson (2010) refers to this as a respondent system in the system coupling diagram. The intervention system is the system that is to be realized (or conceived and brought into being) in order to address some perceived problem in the context as shown in Figure 3.

The realization system can be a service system (as described in knowledge area Service Systems Engineering) or an enterprise system (as described in the knowledge are Enterprise Systems Engineering). When the realization system is a service system, then the service could partially realize the system by just designing the product system without developing or creating it. This design service system can pass the design to a manufacturing service system that turns the design into a physical artifact. Usually an enterprise is established to orchestrate the disparate services into a cohesive whole that is efficiently and effectively performed to achieve the strategic goals of that enterprise.

The product realization system utilizes a product realization process as described in (Magrab et al 2010) or a product development process as described in (Wheelwright and Clark 1992).

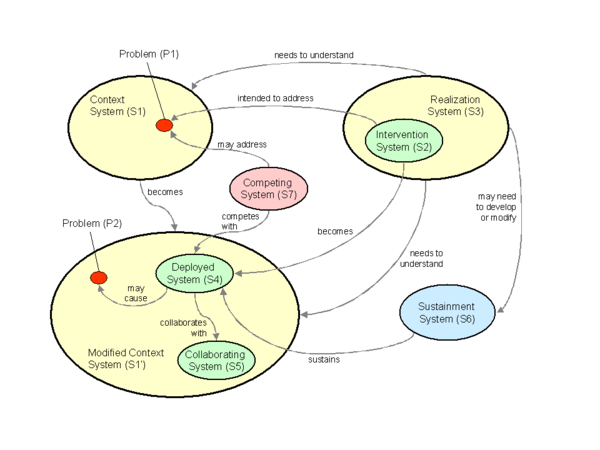

Product Sustainment System

When the realization system delivers the product system into its intended environment, the product often needs a set of services to keep that product operational. This other system, when needed, is called the product sustainment system. It consists of various enabling products and operational services. The sustainment system in relation to the realization system and the deployed product system is illustrated in Figure 4. Notice that the realization may need to develop or modify the sustainment for the particular intervention (product) system under development.

Product Systems Engineering, Service Systems Engineering and Enterprise Systems Engineering

PSE is in line with Traditional Systems Engineering (TSE) as captured in most textbooks on the subject, such as Wasson (2006), Sage and Rouse (2009), and Blanchard and Fabrycky (2011). However, they do not cover the full breadth of PSE since they tend to focus on hardware and software products only. Other kinds of products to be engineered include personnel, facilities, data, materials, processes, techniques, procedures, and media (Martin 1997; Lawson 2010). Further discussions on the distinctions between the various kinds of products is provided in the Product Systems Engineering Background article. Product system domains could be data-intensive (e.g. transportation system), facilities-intensive (e.g. chemical processing plant), hardware-intensive (e.g. defense systems), or technique-intensive (e.g. search and rescue system). Most product systems are a composite of several different kinds of products that must be fully integrated to realize the complete value added potential for the different stakeholders.

When compared to Service Systems Engineering (SSE) and Enterprise Systems Engineering (ESE), PSE has some unique considerations:

- Often a product is part of a product line where both the product line and the products that make up that product line must be engineered simultaneously.

- Products are often composed of parts and sub-assemblies produced by several suppliers. This entails the need to work closely with the supply chain to ensure a successful product offering.

- Large complex products often require a lengthy and complicated series of steps for assembly, integration and test. During integration, many of the key assumptions made during the initial product design could be challenged.

- Products will usually require certification as to their safety or other factors like energy conservation and environmental compatibility. Electronic products often require certification to ensure electromagnetic compatibility and limited electronic emissions into the radio frequency spectrum. Transportation products require certification for safe operations.

- Products often have a complicated distribution network since they are not always developed where the end user may require it. There could be depots, warehouses, multi-modal transportation, wholesalers, dealers, and retail stores as part of this distribution network. This introduces challenges in delivery, maintenance and support of the product.

- Products must be engineered along with the realization system and the sustainment system. Sometimes it is necessary to make tradeoffs between the features and functions of the product system, the realization system and the sustainment system.

These considerations and others will be addressed in the articles under this knowledge area. One of the responsibilities of ESE is to manage these various considerations across multiple product lines across the enterprise while maximizing profits and customer satisfaction. SSE is often dependent on the products resulting from the PSE. A service will often be based on a product infrastructure that includes elements like data processing, hardware, software, data storage, data entry devices, display devices, service delivery facilities and techniques, service desk technicians, maintenance personnel, service offering catalogs and printed materials. Each of these products in the service infrastructure may need to be separately engineered using its own PSE lifecycle.

Creating Value

An enterprise that creates products must also create value in the eyes of the customer; a value that exceeds the cost of that product. This applies to both private and public enterprises operated for profit or not-for-profit. The creation and delivery of products may be the result of an acquisition agreement or an offering directly to buyers or users. To remain competitive, enterprises also need to understand the effects of the global economy, trends in industry, technology development needs, effects of new technology breakthroughs, market segments creation and their expectations, and most importantly, ever evolving customer expectations.

Ring (1998) defines a system value cycle with three levels that a systems approach must consider to deliver real world benefit:

- stakeholder value

- customer need

- system solution

Value will be fully realized only when it is considered within the context of time, cost, and other resources appropriate to key stakeholders.

Aligning product characteristics with associated operational activities=

The user of a product views the product as an asset that can be utilized in one's own systems of interest (Lawson 2010). Thus, in supplying the product, the expected form of operation becomes a driving factor in determining the characteristics of the product. In several contexts, in particular for military related products, the desired operational activities are termed concept of operations (ConOps) and in the case of commercial enterprises the intended use of the system is described through some form of Market Service Description of the product. The intended use of the product is market/customer driven and so the product characteristics must be aligned with the operational intent.

Architectures as basis for value assessment

Architectures can be used by enterprises to shift product development from individual products to an underlying product line architecture that incorporates the flexibility required by the enterprise to rapidly tailor new technologies and features to specific customer requirements (Phillips 2001). In determining the architecture of the product system, various alternative designs may arise. Each of the architecture alternatives is to be evaluated with respect to its value contribution to end users and other stakeholders.

Role of evaluation criteria in selection between product alternatives

In assessing the product system value, one must consider the measures that are to be used to determine the goodness of the product alternatives (alternative architectures and technologies) with respect to producibility, quality, efficiency, performance, cost, schedule and most importantly the coverage provided in meeting the customer’s requirement or market opportunity.

Role of tradeoffs in maximizing value

The evaluation of alternatives must include the tradeoffs between conflicting properties. For example, in striving for superior quality and efficiency, tradeoffs must be made with respect to schedule and cost. See article on Measurement in Part 3. Tradeoffs are made during different stages of the development process: at the product or system level, at the subsystem and architecture definition level, and at the technology level (Blanchard and Fabrycky 2011).

There are a variety of methods for performing tradeoff analysis such as: utility theory, analytic hierarchical process, the Pugh selection method, multi-objective decision, multi-attribute utility analysis, and multi-variate analysis. For software, the Software Engineering Institute (SEI) provides 'The Architecture Tradeoff Analysis Method (ATAM)' (Kazman et al., 2000) for evaluating software architectures relative to quality attribute goals. ATAM evaluations expose architectural risks that potentially inhibit the achievement of an organization's business goals. The ATAM not only reveals how well an architecture satisfies particular quality goals, but also provides insight into how those quality goals interact with each other and how they trade off against each other.

Expanding role of software in creation of product value

Software has an increasing role in providing the desired functionality in many products. The embedding of software in many types of products (such as transportation vehicles, home appliance, and production equipment) accounts for an ever increasing portion of the product functionality. The current trend is the development of a network of systems that incorporate sensing and activating functions. The use of various software products in providing service is described in the Service Systems Engineering knowledge area.

References

Works Cited

ANSI/EIA. 2003. Processes for Engineering a System. Philadelphia, PA, USA: American National Standards Institute (ANSI)/Electronic Industries Association (EIA). ANSI/EIA 632‐1998.

Blanchard, B.S., and W.J. Fabrycky. 2011. Systems Engineering and Analysis, 5th ed. Prentice-Hall International series in Industrial and Systems Engineering. Englewood Cliffs, NJ, USA: Prentice-Hall.

ISO/IEC/IEEE. 2011. Systems and software engineering - Architecture description. Geneva, Switzerland: International Organization for Standardization (ISO)/International Electrotechnical Commission (IEC)/Institute of Electrical and Electronics Engineers (IEEE), ISO/IEC/IEEE 42010.

Kazman, R, M. Klein, and P. Clements. 2000. ATAM; Method for Architecture Evaluation. Pittsburg, PA, USA: Software Engineering Institute (SEI)/Carnegie Mellon University (CMU). CMU/SEI-2000-TR-004, ESC-TR-2000-004.

Lawson, H. 2010. A Journey Through the Systems Landscape. London, UK: College Publications, Kings College, UK.

Magrab, E., S. Gupta, P. McCluskey, and P. Sandborn. 2010. Integrated Product and Process Design and Development - The Product Realization Process. Boca Raton, FL, USA: CRC Press.

Martin, J.N. 1997. Systems Engineering Guidebook: A process for developing systems and products, 1st ed. Boca Raton, FL, USA: CRC Press.

Martin, J. 2004. "The Seven Samurai of Systems Engineering: Dealing with the Complexity of 7 Interrelated Systems." Proceedings of the International Council on Systems Engineering (INCOSE) International Symposium, Toulouse, France, 2004.

Phillips, F. 2001. Market-oriented Technology Management - Innovating for Profit in Entrepreneurial Times. Berlin, Germany: Springer-Verlag.

Pugh, S. 1990. Total Design: Integrated Methods for Successful Product Engineering. Upper Saddle River, NJ, USA: Prentice Hall.

Ring, J., 1998. "A Value Seeking Approach to the Engineering of Systems." Proceedings of the IEEE Conference on Systems, Man, and Cybernetics. p. 2704-2708.

Sage, A., and W. Rouse. (eds.) 1999. Handbook of Systems Engineering and Management. Hoboken, NJ, USA: John Wiley and Sons, Inc.

Wasson, C.S. 2006. System Analysis, Design, and Development. New York, NY, USA: John Wiley & Sons.

Wheelwright, S. and K. Clark. 1992. Managing New Product and Process Development: Text and Cases. Columbus, OH, USA: Free Press.

Primary References

ANSI/EIA. 2003. Processes for Engineering a System. Philadelphia, PA, USA: American National Standards Institute (ANSI)/Electronic Industries Association (EIA). ANSI/EIA 632‐1998.

Blanchard, B. S., and W. J. Fabrycky. 2011. Systems Engineering and Analysis, 5th ed. Prentice-Hall International series in Industrial and Systems Engineering. Englewood Cliffs, NJ, USA: Prentice-Hall.

Martin, J. 2004. "The Seven Samurai of Systems Engineering: Dealing with the Complexity of 7 Interrelated Systems". Proceedings of the International Council on Systems Engineering (INCOSE) International Symposium, Toulouse, France, 2004.

Wasson, C. S. 2006. System Analysis, Design, and Development. New York, NY, USA: John Wiley & Sons.

Additional References

None.

SEBoK Discussion

Please provide your comments and feedback on the SEBoK below. You will need to log in to DISQUS using an existing account (e.g. Yahoo, Google, Facebook, Twitter, etc.) or create a DISQUS account. Simply type your comment in the text field below and DISQUS will guide you through the login or registration steps. Feedback will be archived and used for future updates to the SEBoK. If you provided a comment that is no longer listed, that comment has been adjudicated. You can view adjudication for comments submitted prior to SEBoK v. 1.0 at SEBoK Review and Adjudication. Later comments are addressed and changes are summarized in the Letter from the Editor and Acknowledgements and Release History.

If you would like to provide edits on this article, recommend new content, or make comments on the SEBoK as a whole, please see the SEBoK Sandbox.

blog comments powered by Disqus